Regular maintenance

Ø39mm Bar Capacity · Ø320mm Plate Turning · 280/330mm Axis Travel · Compact High-Performance Lathe

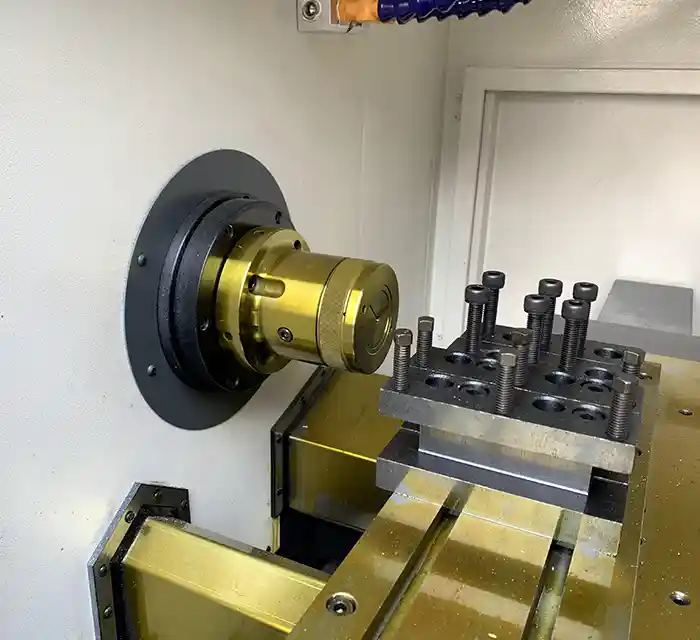

The MN32i is a compact, high-rigidity flat-bed CNC lathe designed for bar and disc part machining with outstanding precision and clamping force. Supporting a maximum bar capacity of Ø39mm and a turning diameter of up to Ø320mm, with 280mm X-axis and 330mm Z-axis travel, it delivers stable performance, long tool life, and high-speed productivity in a minimal footprint.

MN32i

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● Max. Bar Capacity Ø39mm: Ideal for feeding through small shafts, pins, and connector parts using bar feeders.

- ● Max. Turning Diameter Ø320mm: Enables the machining of wider disc components or flanges with a flat-bed configuration.

- ● Travel Range: X = 280mm / Z = 330mm: Supports compact, high-efficiency operations for small-to-mid size workpieces.

- ● Flat-Bed Design with Powerful Clamping: Enhances operational rigidity, particularly for bar-fed or high-force turning applications.

- ● High-Speed, Servo-Driven Turret: Enables quick tool changes for multi-step operations and tight cycle times.

Recommended Configurations

- ● Spindle: High-precision spindle (SKF, NSK), center-out water spindle, hydraulic spindle

- ● Drive System: Servo motor, linear motor drive (high precision, high speed)

- ● Automation: Automatic tool changing system (ATC), automatic loading and unloading system, robotic arm integration

- ● Turret: Electric turret, servo turret, Y-axis powered turret, vertical electric tool holder

- ● Cooling System: High-pressure cooling system, built-in cooling system

- ● CNC Control System: High-performance CNC systems (FANUC, Siemens, GSK, KND, SYNTEC, Mitsubishi, etc.)

- ● Measurement and Monitoring: Tool breakage detection system, Renishaw OMP60 workpiece probe, Renishaw TS27R contact tool setter

- ● Other Configurations: Hydraulic/pneumatic chuck, protective cover design, chain-type chip conveyor, oil mist collector

Application Case

- ● Client: Fastener manufacturer (Eastern Europe).

- ● Workpiece: Alloy steel bolt head, Ø36mm × 45mm.

- ● Setup: H32i + bar feeder + 8-tool servo turret.

- ● Results: 12-hour unattended production shift, Tolerance held within ±0.005mm, Clean thread finishing with minimal burrs, Cycle time per piece: 28 seconds.

Product Specifications

| Specifications | unit | MN32i |

|---|---|---|

| Max.swing dia.over bed | mm | 320 |

| Max.swing dia.over slide | mm | 70 |

| Max.processing length | mm | 280 |

| Max.bar capacity | mm | 39 |

| Max.processing diameter(plate) | mm | 320 |

| Spindle nose | GB59001 | A2-5 |

| spindle bore | φ/mm | 48 |

| Spindle speed | r/min | 50-4000 |

| Spindle shift mode | / | stepless speed control |

| Spindle motor power | KW | 3.7 |

| Chuck type | / | Hydraulic collets/chucks |

| Chuck size | Inch | 6 |

| Xaxis rapid traverse | m/min | 24 |

| Zaxis rapid traverse | m/min | 24 |

| Xaxis servo motor torque | N.m | 4 |

| Zaxis servo motor torque | N.m | 4 |

| Xaxis travel | mm | 280 |

| Zaxistravel | mm | 330 |

| Guide waytype | / | rails |

| Toolpostype | / | spatula |

| Toolshank size | mm | 20×20/025 |

| Total rated power | Kw | 6 |

| Totalrated current | A | 13 |

| Net weight | kg | 1400 |

| Machine dimension(LxW×H) | (mm) | 1620×1420×1700 |

Catalog

Frequently Asked Questions

Flat bed CNC lathes are suitable for steel, cast iron, copper, aluminum, and other metal materials, especially for high-precision and mass production.

The maximum machining diameter of common flat bed CNC lathes ranges from 300mm to 1000mm, depending on the model.

As a professional CNC lathe machine manufactor, Minnuo offers direct factory sales. We will provide the most suitable quotation according to customers' requirements to ensure the highest cost - performance ratio.

Minnuo's pre - sales team responds quickly. For a single flat bed lathe, we'll give equipment recommendations within 10 minutes upon getting the drawings. For a production line of multiple CNC machine lathes, a solution will be provided within 5 working days.

We have complete basic production equipment.We customize the CNC lathe machine components like machine systems, spindle speeds, motor power, and outer shell sheet metal.

Our top - brand processing machines ensure part machining accuracy in CNC lathe machines. We provide quality inspection reports for CNC machine lathes at factory - leaving.

We stock standard Flat bed CNC lathes for quick delivery. Custom flat bed CNC lathe are delivered in 30 - 45 working days.

Our CNC lathe machines have a one - year warranty with free repairs. Contact our 24/7 after - sales team for malfunctions. Issues are resolved via remote video, phone, or on - site service.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Free Quote, Fast Response!

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763