Regular maintenance

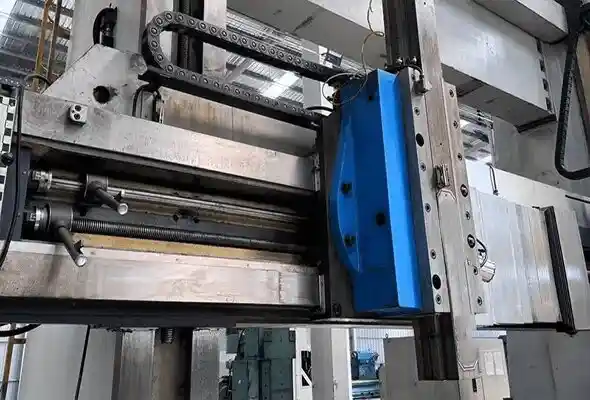

Dual Ball Screw Lifting System • High Load-bearing Capacity • Enhanced Stability

The CK51-BD Series Dual Ball Screw Heavy-duty CNC Vertical Lathe is engineered for high rigidity, stability, and precision, making it ideal for machining large and complex workpieces. Equipped with dual ball screw lifting systems for the crossbeam, this machine offers exceptional cutting capabilities, capable of handling rough, semi-precision, and precision operations on various metals and non-metallic parts.

CK51-BD Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● Dual Ball Screw Lifting: Enhances the machine’s stability and precision during heavy-duty operations.

- ● High-Rigidity Structure: The column, bed, and crossbeam are designed for high stiffness, ensuring excellent vibration resistance.

- ● Precision Spindle Design: High-precision adjustable radial clearance double-row cylindrical roller bearings and large thrust ball bearings provide exceptional rotation accuracy and high load-bearing capacity.

- ● Thermally Symmetrical Structure: Minimizes thermal deformation for consistent performance under high-stress conditions.

- ● Ultrasonic Quenching: Guide surfaces treated with ultrasonic quenching for hardness up to HRC 48-55, improving wear resistance and durability.

Recommended Configurations

- ● Spindle System: High-precision Spindle, High-torque Spindle, Center Water Outlet Spindle

- ● Feed System: High-precision Servo Motor, Stepper Motor, Linear Guides, Ball Screws

- ● Cooling System: Centrifugal Pump, Vibration Pump, Water-soluble Coolant, Oil-based Coolant

- ● CNC Control System: High-performance CNC System, High-precision CNC System, Multi-axis Linkage Control

- ● Tooling System: Turret Tooling System, Electric Turret, Tool Management System

- ● Measurement and Monitoring: Heidenhain Linear Scales, Tool Breakage Detection System, Renishaw OMP60 Workpiece Probe, Renishaw TS27R Tool Setting Probe

- ● Other Configurations: Chip Conveyor, Oil Mist Collector, Oil Cooler, Cooling Water Tank, Automated Robot Arm (Improves Production Efficiency, Suitable for High-volume Processing)

Application Case:

- ● Client: Industrial Component Manufacturer – United States

- ● Use Case: Precision turning of industrial components and large mechanical parts

- ● Setup: CK51-BD Series with Servo Spindle Motor, Electric Knife Table, and Automatic Chip Removal

- ● Results: • Turning Accuracy: Maintained high precision with tolerances of ±0.005mm • Increased Productivity: Overall machining time reduced by 25% • Enhanced Performance: No thermal deformation issues, even during heavy-duty operations

- ● Client Feedback: “The CK51-BD series has greatly improved our machining efficiency, especially for large, high-precision parts. The machine’s stability and cutting power have exceeded our expectations.”

Product Specifications

0

Catalog

Frequently Asked Questions

The Dual Ball Screw Heavy-duty CNC Vertical Lathe offers higher precision and stronger load capacity compared to traditional CNC vertical lathes. The dual ball screw system ensures smoother and more precise movement, making machining more stable. It is especially suitable for high-load and large workpieces, providing superior rigidity and stability for heavy-duty and high-precision machining needs.

The Dual Ball Screw Heavy-duty CNC Vertical Lathe is widely used in industries such as aerospace, automotive, mold making, energy, shipbuilding, and metallurgy. It is particularly suitable for machining large, heavy, and complex workpieces such as shafts, flanges, gears, and wheels, offering high precision and efficiency in machining.

The operation of the Dual Ball Screw Heavy-duty CNC Vertical Lathe is relatively easy, equipped with advanced CNC systems and a user-friendly interface. With the intuitive operating system, operators can quickly grasp basic operating skills and machining parameters. We also provide customized training and detailed operation manuals to help users adapt quickly and improve production efficiency.

Minnuo Company has a strong and responsive pre-sales team. As long as you provide parts drawings, we can provide equipment recommendations for the Dual Ball Screw Heavy-duty CNC Vertical Lathe within 10 minutes. For a production line consisting of multiple machines, we will provide a solution within 5 working days.

Minnuo Company has complete basic production equipment. We offer customization services for the Dual Ball Screw Heavy-duty CNC Vertical Lathe, including machine systems, spindle speeds, motor power, bed size, and even custom tooling and fixtures according to customer needs.

Our company is equipped with several international top-brand processing machines to ensure the machining accuracy of components in the Dual Ball Screw Heavy-duty CNC Vertical Lathe. All equipment undergoes strict quality inspections before leaving the factory, and we provide detailed quality inspection reports to ensure that each machine meets high precision and reliability standards.

For standard models of the Dual Ball Screw Heavy-duty CNC Vertical Lathe, we keep stock and can deliver quickly. For customized models, delivery typically takes 30 to 45 working days.

Our Dual Ball Screw Heavy-duty CNC Vertical Lathe equipment comes with a one-year warranty, and free repair services are provided during the warranty period. If the equipment malfunctions, customers can contact our after-sales team at any time. We offer 24-hour technical support, and issues can be resolved quickly through remote video, phone consultations, or on-site services.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Free Quote, Fast Response!

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763