Regular maintenance

Max. rolling O.D.: φ45mm,Max. rolling length: 4000mm,Max. rolling pressure: 17 tons

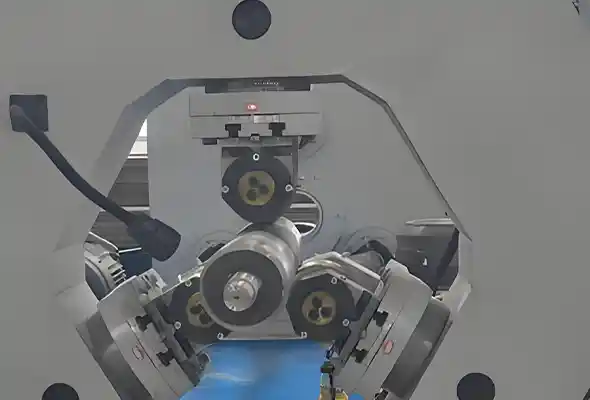

The R17NC-II (Through-feed) is a high-end CNC 3-axis thread rolling machine designed for long-part, uninterrupted thread forming. With a rolling capacity of up to φ45mm in diameter and 4,000mm in length, it brings unmatched precision and durability to production lines that demand high-strength, burr-free thread forms on extended components.

R17NC-II Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● Through-feed rolling up to 4,000mm part length for uninterrupted operations

- ● Max. rolling diameter of φ45mm, ideal for medium and large-size fasteners

- ● High rolling pressure of 17 tons to form threads and splines in tough materials

- ● CNC 3-axis control ensures die positioning, pressure, and feed are precisely managed

- ● Supports full automation and robotic integration for mass production

- ● Suitable for high-strength threads, splines, and knurled forms

- ● Minimal heat and no material loss during plastic deformation process

Recommended Configurations

- ● Servo-powered roller feeder: Ensures steady feed of 4m-long bars.

- ● High-strength thread roll dies: Customized for metric, trapezoidal, or UNC threads.

- ● Integrated mist coolant system: Enhances surface finish and reduces tool wear.

- ● Extended base with roller support: Prevents deflection during long-part operation.

- ● Laser thread sensor: Real-time monitoring for deviation and thread pitch control.

- ● Safety enclosure with light curtain: Industrial-grade protection for continuous rolling.

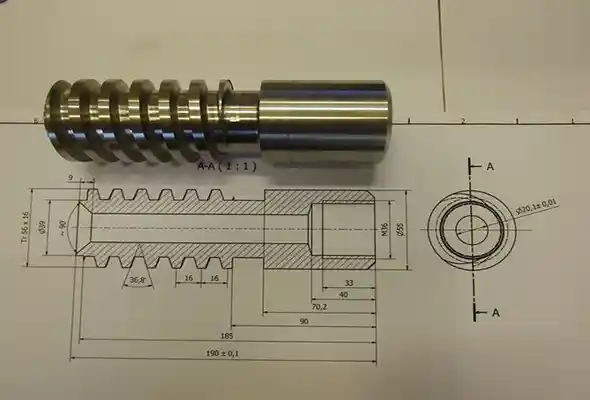

Application Case

- ● Client: Energy Equipment Manufacturer – United Kingdom.

- ● Use Case: Rolling of 3.8m anchor rods with trapezoidal threads for wind turbine base systems.

- ● Setup: R17NC-II with programmable 3-axis CNC, auto feeder, and trapezoidal roll dies.

- ● Results: Thread pitch accuracy: ≤ ±0.015mm across full length, output: 80+ rods per hour, continuous shift operation, surface finish: Ra ≤ 1.0 μm with no secondary finishing required, client feedback: “The precision and stability over long parts make this machine the backbone of our high-torque anchoring systems.”

Product Specifications

0

Catalog

Frequently Asked Questions

Minnuo’s thread rolling machines can form metric threads, inch threads, trapezoidal threads, knurling, splines, and custom straight/diagonal patterns, suitable for a wide range of fasteners and shafts.

Thread rolling works best on mild steel, carbon steel, stainless steel, copper, aluminum, and titanium alloys. It is ideal for materials with good plasticity and cold-forming properties.

Thread rolling provides stronger threads, faster production, better surface finish, and no chip waste. It also improves fatigue resistance and dimensional consistency.

Yes! Just send us your product drawings or basic specifications (thread type, material, diameter, length), and we’ll recommend the right thread rolling machine model within 10 minutes.

Absolutely. We offer customization for thread pitch range, roller type, rolling force, control system (manual, hydraulic, CNC), and automatic feeding systems to suit your production needs.

We use hardened and ground guideways, servo or hydraulic pressure control, and calibration through sample test rolling, with dimensional inspection reports provided before delivery.

Standard models are delivered in 10–15 working days. Custom-built or automated models typically require 20–30 working days, depending on complexity.

Minnuo provides a one-year warranty, 24/7 technical support, video training, on-site assistance, and lifetime spare parts support.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Free Quote, Fast Response!

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763