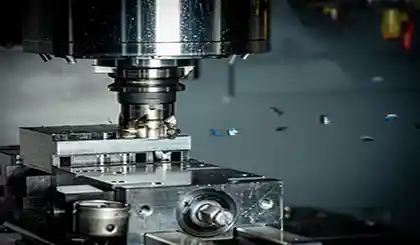

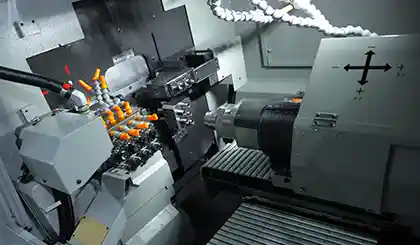

What is Angle Milling: Principles and High-Precision Machining Solutions

Angle Milling has become a key technique for efficiently machining inclined surfaces, significantly impacting the performance, structural strength, and overall reliability of assembled components.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763