How to Choose the Right Type of Turret for CNC Machine Tools?

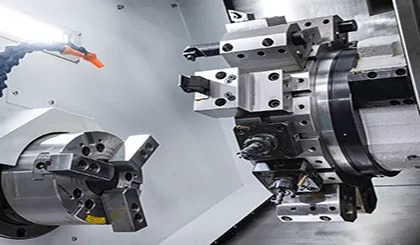

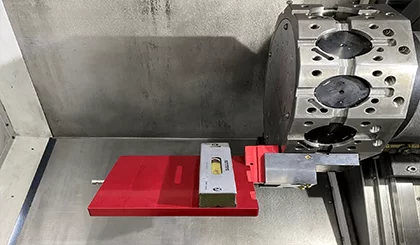

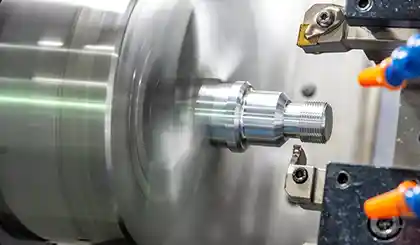

The turret is the key mechanism in CNC machines responsible for mounting and changing tools. Common turret types include electric turrets, hydraulic turrets, servo turrets, and live (powered) turrets. Choosing the most suitable one requires a comprehensive consideration of machining requirements, cost budget, maintenance capabilities, and other factors.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763