What are the Differences Between Vertical and Horizontal Lathes?

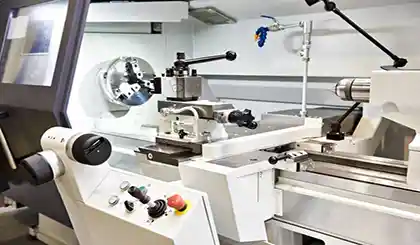

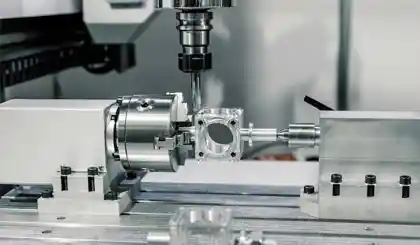

As core processing equipment, the selection of lathes directly impacts an enterprise’s production efficiency, product quality, and cost control. Vertical lathes, with vertical spindles, are ideal for processing large, disk-shaped, and ring-shaped parts, where gravity aids in stabilizing the workpiece. Horizontal lathes, with horizontal spindles, are more suitable for processing shaft-type and sleeve-type parts, with easier axial feeding.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763