Common faults in 5-Axis Machining Center processing: Fast tool wear, rough surface? Product Adaptation and Process Adjustment Guidelines

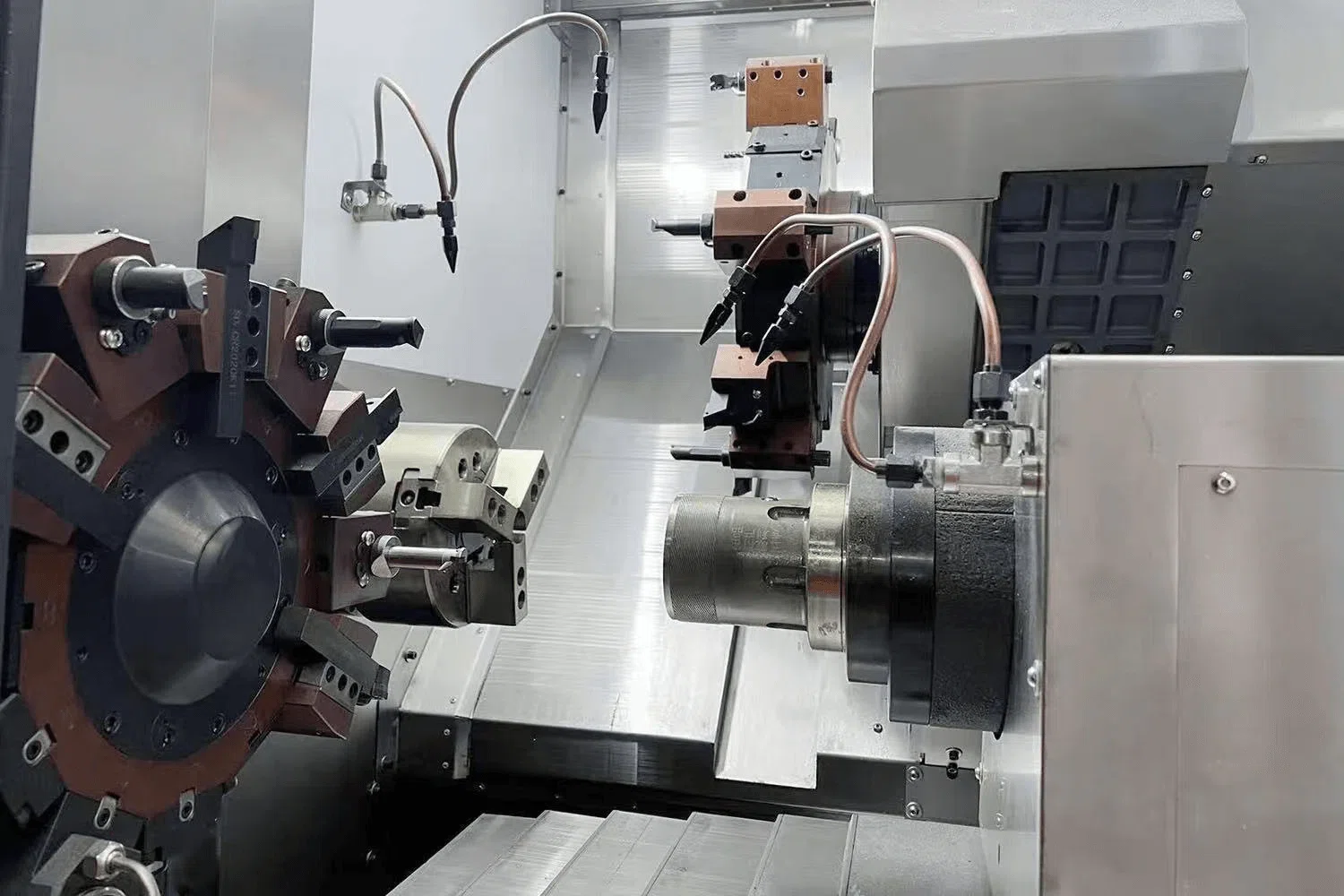

To address the core issue of "common faults in 5-Axis Machining Center processing: rapid tool wear and rough surface", it is necessary to first clarify the essence of the fault - 90% of such problems do not stem from equipment performance defects, but are the result of the combined effect of "product mismatch" and "inappropriate process parameters". A mismatch between the hardness of the cutting tool material and that of the workpiece can lead to insufficient red hardness of the cutting tool, reducing its service life by 70% sharply. Substandard precision of auxiliary tools can cause fluctuations in cutting force and accelerate local wear at the tool tip. However, process issues such as excessively high feed rates and lack of cooling and lubrication will directly lead to coarsening of the cutting marks and the appearance of "tool biting marks" on the surface, causing the roughness to exceed the standard.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763