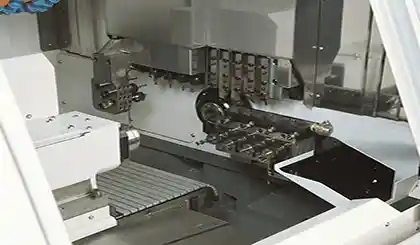

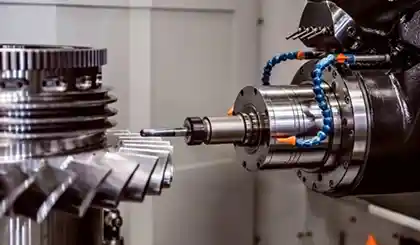

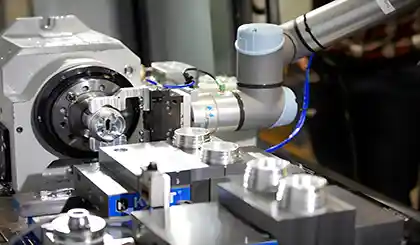

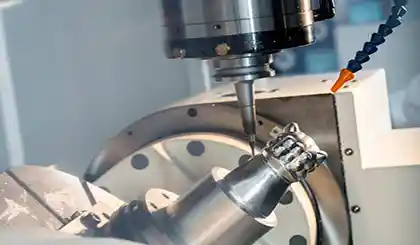

Guide Bushings for Swiss Lathes: Everything You Need to Know

As the core positioning element of Swiss lathes, guide bushings ensure both IT5 level precision control and high-speed machining stability through rigid support and dynamic balance technologies. They are the key technological enabler for breaking through the bottleneck in precision machining.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763