Regular maintenance

High-speed drilling and tapping machining center TC1365

-

Bench size (length and width): 900×400mm

-

Triaxial stroke (X / Y / Z): 800/400/300

-

Maximum carrying capacity: 300kg

-

Main shaft speed: 20000rpm

Bench Size: 900 × 400 mm · X/Y/Z Travel: 800 / 400 / 300 mm · Max Load: 300 kg · Spindle Speed: 20,000 rpm

The TC-1365 is a high-speed CNC drilling and tapping center designed with a balanced axis range and a compact footprint, perfect for medium-length components or dual-part clamping. Its 20,000 rpm high-speed spindle and 800mm X-axis travel deliver exceptional flexibility for repetitive hole processing, making it a productivity booster for factories needing high-output, high-accuracy setups.

TC1365 Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● 20,000 RPM BT30 Spindle: Enables ultra-clean drilling and thread forming with minimal cycle time.

- ● Extended X-Axis (800mm): Perfect for dual-station fixtures, medium-size aluminum plates, or long component bases.

- ● 300kg Table Load with 900mm Length: Suitable for light-duty fixtures and multi-part batch clamping.

- ● Z-Axis Travel of 300mm: Supports parts up to medium depth with stable downward rigidity.

- ● Compact Body with Servo Precision: Enables fast motion, high-speed positioning, and tight space integration.

Recommended Configurations

- ● 20-Tool ATC System: Increases speed during multi-process jobs.

- ● Dual-Part Clamping Fixture: Doubles throughput for symmetrical or repetitive work.

- ● Oil-Mist Cooling System: Ensures longer tool life and better surface finish.

- ● Part Probing System: Speeds up setup and increases first-piece accuracy.

- ● MQL or High-Pressure Coolant: Enhances chip evacuation during deep or blind hole drilling.

Application Case

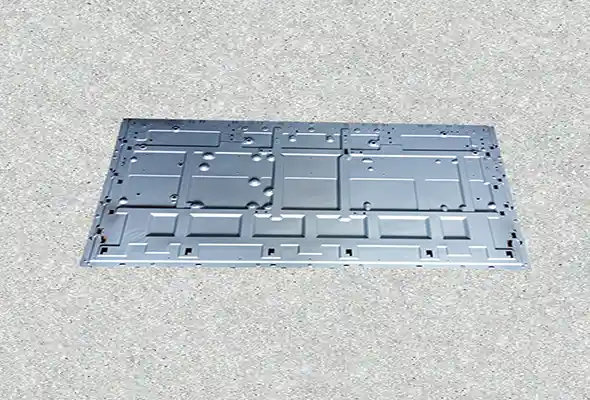

- ● Client: Control Panel Manufacturer – Southeast Asia.

- ● Use Case: Multi-hole processing for aluminum electrical backplanes.

- ● Setup: TC-1365 with dual-station pneumatic fixture + 20-tool ATC.

- ● Results: 60 holes tapped within 40 seconds, accuracy maintained across both parts within ±0.01 mm, feedback: “We doubled productivity while maintaining stable thread quality.”

Product Specifications

| Name | Unit | Parameter | |

|---|---|---|---|

| Range of work | Triaxial stroke(X/Y/Z) | mm | 1300/650/300 |

| The distance from the main nose to the working top | mm | 150~450 | |

| Workingbench | Bench size(length and width) | mm | 1400×650 |

| Maximum carrying capacity | kg | 450 | |

| T-type groove(slot number,slot width spacing) | 5×14×120 | ||

| Spindle | Spindle diameter/cone hole | mm | φ100/BT30 |

| main shaft speed | rpm | 20000 | |

| Power of spindle motor | kW | 3.7/5.5 | |

| Speed | Fast moving speed(X/Y/Z axis) | m/min | 30/48/48 |

| Cut into give speed | m/min | 10/10/10 | |

| Tool magazine | Number of knives | grasp | 21 |

| Tool maximum diameter/length/weight of | φ60mm/200mm/3kg | ||

| Maximum diameter(full/adjacent) | mm | 60/80 | |

| Tool exchange time(knife-knife) | S | 1.3 | |

| Machine tool accuracy | Positioning accuracy(X/Y/Z) | mm | 0.010 |

| Repeat positioning accuracy(X/Y/Z) | mm | 0.006 | |

| Else | Specification of straight-line rolling guide gauge(X/Y/Z) | mm | 30/30/35 |

| Ball screw specification(X/Y/Z) | mm | 40/32/32 | |

| Servo motor specification(X/Y/Z) | N.m | 9/13.7/22.5 | |

| Gas source/air pressure | 280L/min 6~8bar | ||

| Total electrical capacity of the machine tool | KVA | 15 | |

| Machine tool external type size(XYZ) | mm | 3300×3220×2900 | |

| Machine tool weight(about) | kg | 4400 | |

Catalog

Frequently Asked Questions

Minnuo’s drilling & tapping centers are ideal for light metal components, such as aluminum brackets, 3C parts, heat sinks, phone casings, and precision automotive parts that require high-speed drilling and threading.

Unlike standard VMCs, drilling & tapping centers are designed for high spindle speed (up to 20,000 rpm), rapid tool change, and fast feed rates, optimized specifically for drilling, tapping, and light milling with shorter cycle times.

Minnuo machines offer positioning accuracy of ±0.005 mm, repeatability ±0.003 mm, spindle speeds up to 15,000–20,000 rpm, and rapid traverse speeds up to 48–60 m/min, ensuring ultra-fast cycle time.

Yes! Just send us your part drawing, material, tapping hole specifications, and production volume. Our engineers will recommend the right drilling & tapping center model within 10 minutes.

Absolutely. We support customizations such as table size, number of tool positions (ATC), spindle taper (BT30/BT40), coolant through spindle (CTS), and integration with automation like robot arms or pallet changers.

We use high-rigidity cast bases, high-speed precision spindles, servo motors, and perform spindle dynamic balance tests, laser calibration, and full test cutting verification before delivery.

Standard models are delivered in 25–35 working days. Customized models or automation-equipped machines typically require 35–45 working days.

Minnuo offers a one-year warranty, 24/7 technical support, online and on-site training, remote troubleshooting, and long-term spare parts support.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763