Regular maintenance

CNC Wire EDM DK77120

-

Worktable size: 270*420mm

-

Worktable travel:200*250mm

-

Max. workpiece height: 200mm

Applications: Mold inserts • stamping punches • sensor brackets • precision shims

The DK77120 is a large-format CNC wire-cut EDM machine designed to tackle extra-large and heavy conductive workpieces. With an expansive 1200 × 1600 mm travel and 500 mm vertical clearance, it supports precise contouring, taper cutting, and profile shaping on oversized dies, thick plates, and complex components.

DK77 Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● Massive Table Capacity (1300 × 1900 mm): Supports heavy workpieces such as automotive die shoes, multi-cavity mold bases, and tooling plates.

- ● Long-Axis Travel (1200 × 1600 mm): Enables full machining of oversized components without repositioning, improving efficiency and alignment accuracy.

- ● 500 mm Max Workpiece Height: Accommodates thick steel blocks or stacked materials, ideal for large tool setups.

- ● Gantry Frame with Precision Guideways: Ensures stability and long-term accuracy, even under heavy loads.

- ● Optional Multi-Axis or Taper Control Head: Available for angled features or 3D-profile cutting.

Recommended Configurations

- ● Automatic Wire Threading: Reduces downtime, ideal for long-cycle operations.

- ● Dual Water Pump System: Ensures strong dielectric circulation for large volume machining.

- ● Taper Cutting System (optional): Enables precision beveling on thick components.

- ● Extended Filtration Unit: Maintains dielectric fluid purity for prolonged cutting stability.

- ● Vacuum Workholding Setup: Useful for large, flat plates prone to thermal distortion.

Application Case

- ● Client: Automotive Stamping Die Manufacturer – Germany.

- ● Use Case: Processing of 1200 × 1500 mm hardened mold base with multiple pocket contours and taper features.

- ● Setup: DK77120 with taper head, dual coolant system, and overhead crane loading.

- ● Results: Accuracy across full travel: ≤ ±0.015 mm, Ra finish: ≤ 2.2 μm, daily continuous operation time: 20+ hours, client feedback: “Unmatched capability for full-size mold cutting with tight tolerances.”

Product Specifications

| Type | Worktable size(mm) | Worktable travel(mm) | Max.workpiece height(mm) | Taper(optional) | Max.workpiece weight(kg) | Machine weight(kg) | Machine dimension(L*H) | Power consumption |

|---|---|---|---|---|---|---|---|---|

| DK7720 | 270*420 | 200*250 | 200 | 60/80mm | 100 | 800 | 1160*880*1400 | AC380V/220V 50Hz |

| DK7725 | 340*520 | 250*220 | 400 | 60~120/80 | 200 | 1200 | 1485*1010*1700 | |

| DK7730 | 340*560 | 300*360 | 400 | 60~120/80mm | 200 | 1250 | 1485*1050*1700 | |

| DK7732 | 380*600 | 320*400 | 400 | 60~300/80mm | 300 | 1400 | 1640*1280*1700 | |

| DK7735 | 380*650 | 350*450 | 400 | 60~300/80mm | 300 | 1440 | 1660*1330*1700 | |

| DK7740 | 410*710 | 400*500 | 400 | 60~600/80mm | 450 | 1600 | 1830*1490*1700 | |

| DK7740B | 450*840 | 400*630 | 400 | 60~600/80mm | 450 | 1670 | 1845*1610*1700 | |

| DK7745 | 500*750 | 450*550 | 400 | 60~600/80mm | 450 | 1650 | 1865*1520*1700 | |

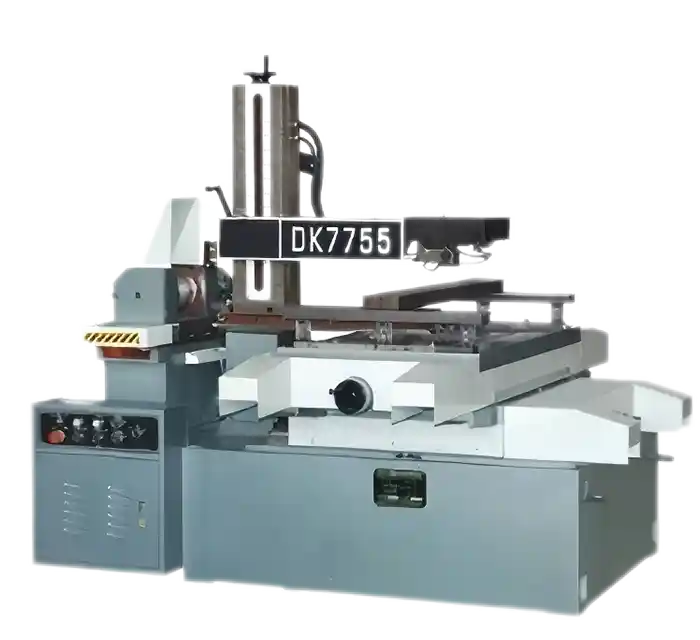

| DK7755 | 596*880 | 550*650 | 500 | 60~600/80mm | 800 | 2500 | 2070*1170*1790 | |

| DK7755B | 596*1060 | 550*850 | 500 | 60~600/80mm | 850 | 2600 | 2070*1950*1790 | |

| DK7763 | 790*1260 | 6300*1000 | 600 | 60~600/80mm | 1000 | 3500 | 2265*2160*1930 | |

| DK7763A | 720*1260 | 630*1000 | 600 | 60~600/80mm | 1000 | 3200 | 2200*2160*1930 | |

| DK7780 | 900*1500 | 800*1200 | 600 | 60~600/80mm | 1500 | 5500 | 2900*2500*2150 | |

| DK7780A | 880*1440 | 800*1200 | 600 | 60~600/80mm | 1500 | 4700 | 2700*2300*1900 | |

| DK7780B | 880*1260 | 800*1000 | 600 | 60~600/80mm | 1500 | 4500 | 2620*2260*1900 | |

| DK77100 | 1010*1500 | 1000*1200 | 600 | 60~120/80mm | 1500 | 5600 | 2930*2500*2000 | |

| DK77120 | 1300*1900 | 1200*1600 | 500 | 60~120/80mm | 4000 | 10000 |

Catalog

Frequently Asked Questions

Minnuo’s wire EDM machines are ideal for precision molds, punches, stamping dies, aerospace components, medical parts, and complex mechanical structures requiring fine, accurate profiles.

Wire EDM can cut hardened steel, stainless steel, tungsten carbide, titanium alloys, copper, aluminum, and even superalloy materials, regardless of hardness.

Our wire EDMs achieve positioning accuracy within ±0.003–0.005 mm and surface roughness down to Ra 0.6–1.2 μm, depending on machine model and cutting parameters.

Of course! Send us your material type, thickness, dimensional tolerances, and part shape, and Minnuo’s engineers will recommend the most suitable wire EDM model within 10 minutes.

Yes! Customization options include worktable size, maximum cutting thickness, automatic wire threading (AWT) systems, high-frequency power supplies, multi-cut programs, and CNC controller upgrades.

We use high-stability Meehanite casting bases, precision linear guides, servo drive systems, laser calibration, and test cutting verification before shipment.

Standard models are delivered within 20–30 working days. Customized models or special configurations require 30–45 working days.

Minnuo offers a one-year warranty, 24/7 technical support, remote troubleshooting, online operator training, and long-term spare parts supply.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763