Regular maintenance

XH1516

-

X-axis travel: 1600mm

-

Y-axis travel: 1500mm

-

Z-axis travel: 750/500mm

-

Spindle speed: 6000/3000rpm

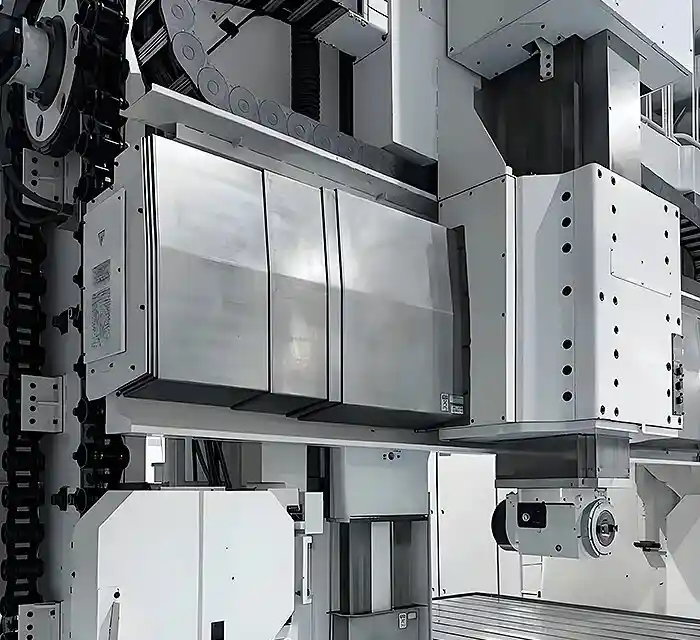

Automatic Shifting Spindle for High-Speed and High-Torque Cutting

The XH1516/XH1625 Series is a high-rigidity gantry machining center built for heavy-duty drilling, milling, and complex machining of large components. With a dual-speed gear-head spindle, through-spindle coolant, CNC rotary table, and fast ATC, it ensures precision, power, and productivity for industrial plates, molds, and structural parts.

XH1516/XH1625

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● Large Travel Range With 1600mm of X-axis travel, 1500mm of Y-axis travel, and a Z-axis range of 750/500mm, this machine offers a versatile platform for a wide range of machining tasks.

- ● High-Rigidity Structure The gantry-style design provides superior rigidity and vibration damping, ensuring precise machining even for large, heavy workpieces.

- ● Spindle Speed Options The machine features spindle speeds of 6000rpm for high-speed milling and 3000rpm for heavier, more demanding operations.

- ● Heavy-Duty Capacity The robust build is ideal for tackling large, complex workpieces with ease, ensuring high precision and minimal distortion during machining.

- ● Optimized CNC Control Equipped with advanced CNC systems for precise control over milling and drilling processes, enhancing automation and overall operational efficiency.

Recommended Configurations

- ● Spindle: High-precision spindle (SKF, NSK), high-speed spindle, air-cooled/water-cooled spindle

- ● CNC Control System: High-performance CNC systems (FANUC, Siemens, GSK, KND, SYNTEC, Mitsubishi, etc.)

- ● Fixtures: Magnetic chuck, V-type fixture, fixed worktable fixture

- ● Drive System: Servo motor drive, linear motor drive, dual-drive system

- ● Tool System: 40-tool chain-type tool magazine, Taiwan-made 24-tool magazine, automatic head changing system

- ● Cooling System: High-pressure cooling system, built-in cooling system, mist cooling system, automatic cutting fluid supply system

- ● Other Configurations: Screw chip conveyor, magnetic hinged belt chip conveyor, gantry loader, Renishaw OMP60 workpiece probe, Renishaw TS27R contact tool setter

Application Case

- ● Client: Aerospace Manufacturer – USA

- ● Use Case: Machining of large, high-precision aerospace components

- ● Setup: XH1520 with automatic tool changer, high-speed spindle, and coolant system

- ● Results: • Dimensional accuracy maintained within ±0.003 mm • Surface finish improved to Ra ≤ 1.5 μm • Production cycle time reduced by 18%

- ● Client Feedback: “The XH1520’s rigidity and precision have made it an invaluable asset in our machining process, allowing us to produce large, high-quality components with incredible consistency.”

Product Specifications

0

Catalog

Frequently Asked Questions

Our drilling and milling gantry machining centers are perfect for large-scale structural parts, such as wind tower flanges, bridge plates, machine tool bases, heavy molds, and rail transit components.

This machine offers strong drilling capacity, powerful milling torque, and multi-process integration, allowing drilling, tapping, milling, and rough-finishing operations to be completed in one setup with high precision and efficiency.

Minnuo’s drilling and milling gantries feature high-rigidity fixed bridge structures, movable rams (Z-axis), servo-driven spindles, automatic tool changers (ATC), and can be equipped with heavy-duty milling heads or multi-spindle drilling heads.

Yes! Send us your part drawings, and our engineers will recommend the best-fit drilling and milling gantry model within 10 minutes. Complete production line solutions can be offered within 5 working days.

Absolutely! We offer customization for spindle types, spindle power, X/Y/Z travel dimensions, table sizes, automatic chip removal systems, CNC controllers, and even automation interfaces.

We use high-grade Meehanite castings, perform laser calibration, spindle dynamic balancing, and full-load trial machining tests before delivery to guarantee excellent accuracy and rigidity.

Standard models are delivered within 45–60 working days. For large customized models, the delivery time may extend to 60–90 working days based on specific configurations.

Minnuo provides a one-year full warranty, 24/7 technical support, remote troubleshooting, on-site services, and guarantees spare parts availability for over 10 years.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763