Regular maintenance

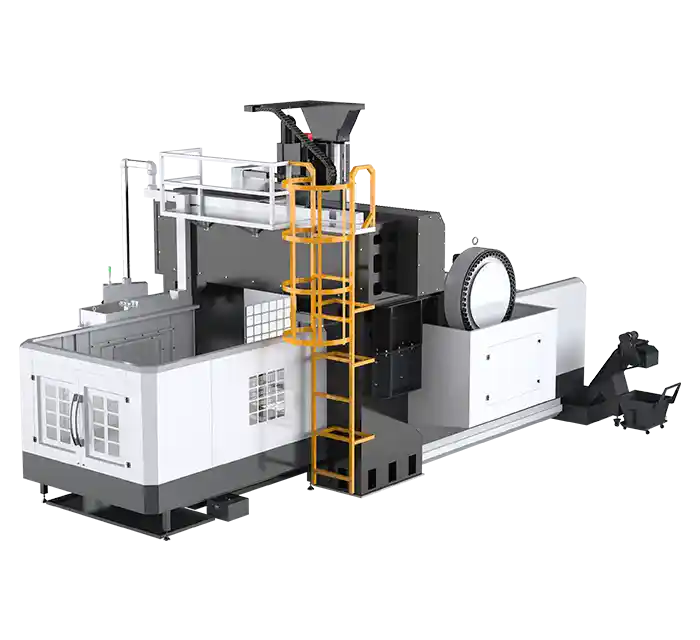

MNG2014

-

Maximum X-Axis Travel: 2100mm

-

Maximum Y-Axis Travel: 1400mm

-

Maximum Z-Axis Travel: 800mm

-

Spindle Speed: 6000rpm

Dual Milling Head Design for Versatile Machining

The MNG2014/MNG6022 Series Moving Table Gantry Machining Center combines robust engineering with high-speed capabilities, offering superior precision for large-scale manufacturing. With its extended X-axis travel of 2600 mm and a versatile Y-axis of 1400 mm, this machine is ideal for high-demand industries requiring large workpieces and intricate machining. The 6000 rpm spindle speed ensures swift material removal and precise finishing.

MNG2014/MNG6022

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● Extended Travel Range With 2600 mm of X-axis travel, this machining center accommodates large parts and complex geometries.

- ● High-Speed Spindle The 6000 rpm spindle is designed for quick material removal, reducing machining time and increasing productivity.

- ● Sturdy Gantry Design The moving table gantry configuration offers high rigidity and stability, even during high-speed operations.

- ● Improved Chip Removal Advanced chip management system ensures a clean working environment and efficient removal of debris.

- ● Flexible Machining Options Capable of handling various materials including metals, composites, and plastics with ease.

Recommended Configurations

- ● Spindle: High-precision spindle (SKF, NSK), high-speed spindle, air-cooled/water-cooled spindle

- ● Spindle: High-precision spindle (SKF, NSK), high-speed spindle, air-cooled/water-cooled spindle

- ● Fixtures: Magnetic chuck, V-type fixture, fixed worktable fixture

- ● Drive System: Servo motor drive, linear motor drive, dual-drive system

- ● Tool System: 40-tool chain-type tool magazine, Taiwan-made 24-tool magazine, automatic head changing system

- ● Cooling System: High-pressure cooling system, built-in cooling system, mist cooling system, automatic cutting fluid supply system

- ● Other Configurations: Screw chip conveyor, magnetic hinged belt chip conveyor, gantry loader, Renishaw OMP60 workpiece probe, Renishaw TS27R contact tool setter

Application Case

- ● Client: Heavy Machinery Manufacturer – USA

- ● Use Case: Machining of large engine components and structural machine parts

- ● Setup: XH2514 with high-speed spindle and automatic tool changer

- ● Results: • Increased machining efficiency by 30% • Achieved precise dimensions within ±0.01 mm tolerance • Reduced tool wear through advanced coolant system

- ● Client Feedback: “The XH2514 has significantly boosted our production rates without compromising on the high precision our clients demand.”

Product Specifications

0

Catalog

Frequently Asked Questions

Our moving table gantry machining centers are ideal for large molds, engine blocks, aerospace panels, heavy mechanical parts, and rail transit components requiring high-precision and multi-surface machining.

Moving table gantries provide better dynamic stability, superior chip evacuation, higher precision for medium to large parts, and easier automation integration due to the independent worktable motion.

Minnuo’s moving table gantries feature fixed gantry structures, moving worktables on precision guideways, high-torque spindles, automatic tool changers (ATC), and optional multi-angle heads.

Absolutely! Minnuo’s engineers can recommend the best-fit moving table gantry machining center model within 10 minutes after reviewing your part drawings. Full production line proposals are available within 5 working days.

Yes! We offer customization for spindle type, travel dimensions (X/Y/Z), worktable size, ATC capacity, milling head types, and automation options such as pallet changers and robotic interfaces.

All machines are built with high-grade Meehanite castings, and undergo laser calibration, dynamic balance testing, and geometric accuracy inspection to guarantee superior precision and reliability.

Standard models are delivered within 40–60 working days. Customized models or special configurations may require 60–90 working days, depending on complexity.

Minnuo offers a one-year warranty, 24/7 technical support, remote troubleshooting, on-site service, and spare parts supply guaranteed for 10+ years.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763