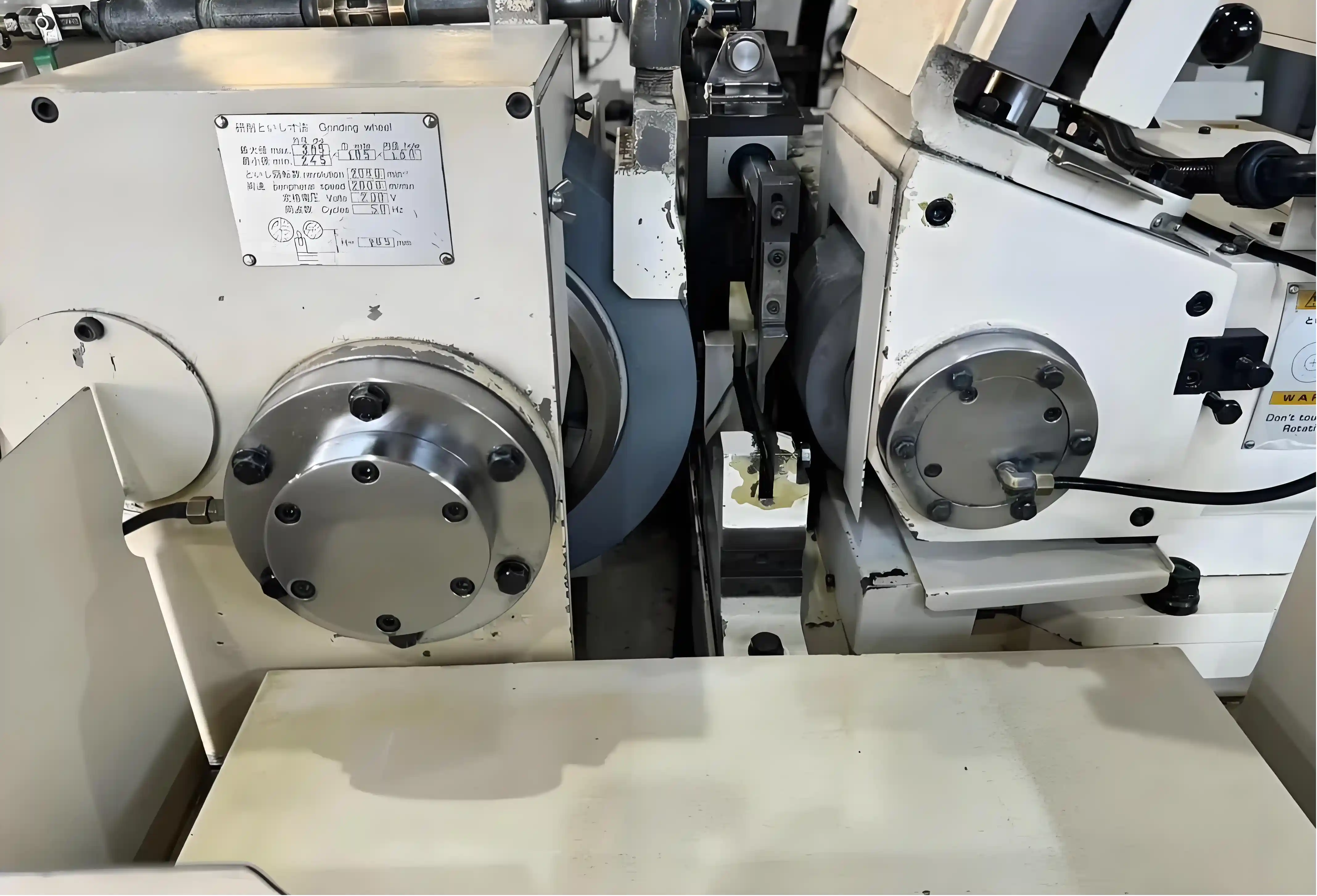

Regular maintenance

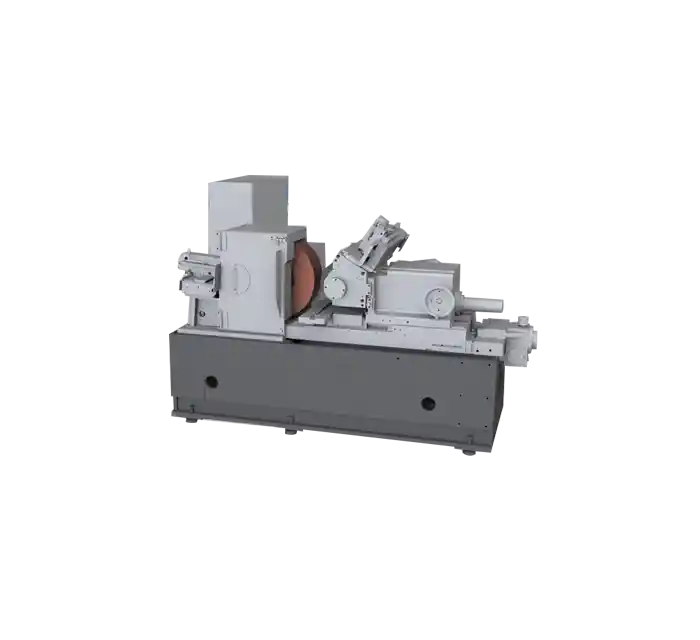

BC6040

-

Range of grinding diameters: Φ1.5-150mm

-

Maximum length of plunge-cut grinding: 400mm

-

Grinding wheel diameter: 610mm

Plunge & through-feed support • Multi-type dresser compatibility • Intelligent lubrication system

The BC Series Centreless Grinding Machine handles plunge and through-feed grinding for Ø0.5–150 mm parts with high rigidity and precision. Optional dressing systems and intelligent features ensure reliable, accurate performance in demanding production environments.

BC Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● High-Rigidity Integrated Grinding Bed: Cast from HT300 material and treated through multi-stage aging, the machine bed achieves a bending stiffness of 4800 N/mm². Its five-way rib structure enhances vibration resistance and ensures long-term machining stability.

- ● High-Precision Ceramic Grinding Wheel: Utilizing CBN or diamond wheels with honeycomb-structured pores for efficient chip removal, the system features 40% stronger bonding for extended wheel life, while dynamic balancing keeps vibration below 0.5 μm to guarantee superior surface finishes.

- ● Intelligent Auto Lubrication: A multi-point centralized lubrication system delivers precise oil supply to lead screws and guideways. Integrated real-time pressure sensors monitor flow and issue alarms for anomalies, minimizing downtime and extending component lifespan.

Recommended Configurations

- ● Spindle and Grinding Wheel System: Hydrostatic or high-speed rolling spindles, grinding wheel spindle motor (frequency control), grinding wheel dressing device (diamond dresser or single-point dresser), grinding wheel dynamic balancing system

- ● Workpiece Clamping and Feeding System: Workpiece feeding device, automatic workpiece positioning and clamping system

- ● Feed System: High-precision ball screws and linear guides, programmable automatic feed control, automatic gap compensation system

- ● Cooling and Chip Removal System: Coolant circulation system and adjustable nozzle-type coolant injection system, paper belt filter, magnetic separator, automatic chip removal system and chip collection device

- ● Control System and Automation: CNC (Computer Numerical Control) or PLC control system, Human-Machine Interface (HMI)

- ● Measuring and Compensation System (Optional): Workpiece online measuring system (contact/non-contact), laser probe or inductive displacement sensor, automatic wear compensation function

Application Case

- ● Client: Automotive Component Supplier – Germany

- ● Use Case: Precision grinding of transmission shafts and valve spools

- ● Configuration: BC Series, profile dresser, linear feedback, oil mist separator

Product Specifications

0

Catalog

Frequently Asked Questions

Absolutely! As long as you provide the part drawings, whether for a single vertical grinding machine or a complete production line, a recommended solution can be provided in a short time. For a single machine, it usually takes about 10 minutes; for multiple machines, the full proposal can be ready in about 5 working days.

Yes. I can customize the spindle power, control system, grinding travel, automatic loading/unloading system, and more on a CNC vertical grinding machine according to the size, material, and machining requirements of my specific workpieces, achieving a perfect match with my production environment.

You can use it with confidence. The components are processed by high-precision mother machines, ensuring high machining accuracy and structural stability. Every vertical grinding machine is rigorously tested before delivery and comes with a complete quality inspection report.

If I choose a standard model, it can usually be delivered quickly. In-stock models can ship as fast as within three days. If I require a customized vertical grinding machine, the delivery time is usually 30 to 45 working days.

We can customize the machine structure, external dimensions, cooling and lubrication system, spindle configuration, control system, and automation modules based on actual production needs. The modular design of the vertical grinding machine also gives me more flexibility for future upgrades.

If you are processing large-size workpieces such as flanges, valve bodies, or ring-shaped parts, a vertical rotary surface grinding machine is especially suitable. Its rotary table structure allows me to efficiently finish precision grinding of large flat components.

We have in-house R&D capabilities, real customer cases, support for customization, and complete after-sales service as vertical grinding machine manufacturers. A stable export record and responsive service ensure long-term, reliable cooperation.

You need to evaluate from several aspects: whether the machine meets my machining requirements, whether flexible customization is supported, whether the quality is stable, and whether technical service is in place. If a manufacturer performs well in solution planning, after-sales response, and application support, they are more likely to be the ideal best vertical grinding machine manufacturer.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763