Regular maintenance

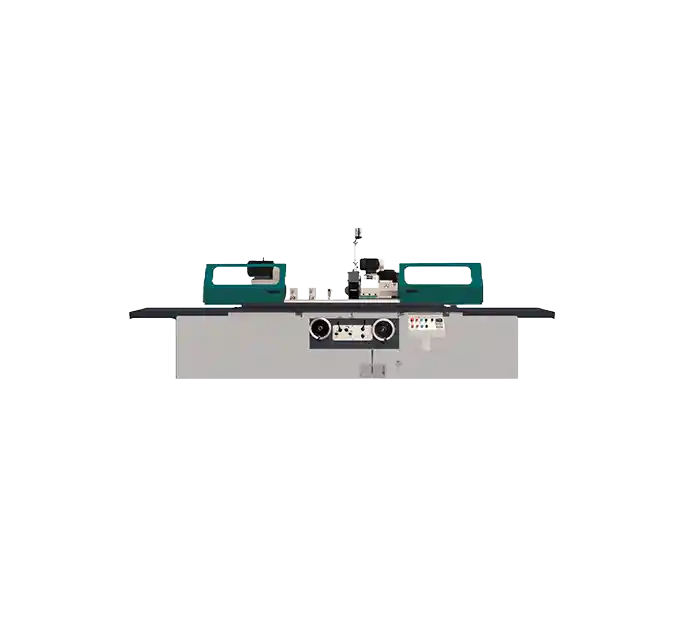

Heavy-Capacity External Cylindrical Grinding Machine M1332

-

Max. length ground(O. D): 1000/1500mm

-

Dia. Ground(O. D): 8~320mm

-

Center height: 180mm

Grinding Diameter: Ø8–320mm · Center Height: 180mm

The M1332 is a high-performance manual cylindrical grinding machine capable of handling long and heavy shaft-type workpieces with excellent accuracy and repeatability. With grinding diameters up to Ø320mm and a maximum length of 1500mm, it is widely adopted for use in maintenance workshops, machinery rebuild shops, and industrial production lines requiring reliable outer diameter finishing.

M13 Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● Extended Length Capacity: 1000/1500mm Supports long shafts, rollers, or tubular parts in one setup without repositioning.

- ● Extra-Wide Diameter Range (Ø8–320mm) Suitable for both slim mandrels and large cylindrical parts like piston sleeves or cylinders.

- ● Manual Table Feed with Smooth Traversing Ensures precise control for both roughing and finishing passes.

- ● Heavy-Duty Cast Iron Base & Columns Deliver vibration suppression and thermal stability for consistent surface quality.

- ● Adjustable Tailstock and Wheel Head Supports taper grinding and precise alignment adjustments as needed.

Recommended Configurations

- ● Spindle and Grinding Wheel System: High-Speed Spindle, Fixed-Speed Spindle Motor, Fixed Grinding Wheel, Adjustable Grinding Wheel

- ● Worktable and Tailstock System: Manual Tailstock Adjustment, Adjustable Worktable, T-slot Worktable

- ● Feed System: High-Precision Ball Screws, Linear Guideways

- ● Cooling and Lubrication: Coolant Injection System, Automatic Lubrication System

- ● Clamping: Standard Fixtures, Pneumatic Fixtures, U-shaped Fixtures

- ● Other: Rotary Chuck, Centers, Follow Rest, Workpiece Measuring Instrument, Grinding Wheel Dressing Fixture, Lighting and Blower System, Human-Machine Interface (HMI), Protective Covers

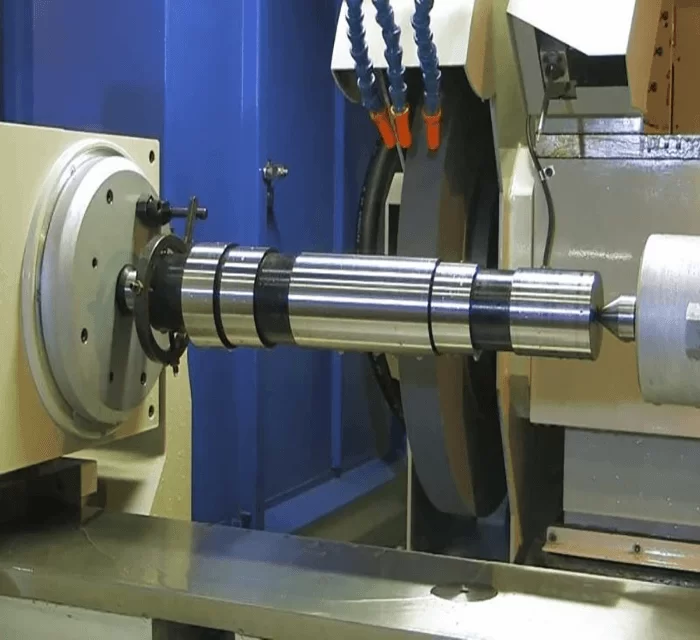

Application Case

- ● Client: Hydraulic Cylinder Repair Shop (Brazil)

- ● Workpiece: Steel cylinder sleeves Ø280×1200mm

- ● Setup: M1332 with steady rest, coolant system, white alumina wheel

- ● Results: Roundness < 4 μm across full length, surface finish: Ra 0.28 μm on heavy sections, setup time reduced by 30% vs split grinding, operators praised manual stability and rigidity under long load.

Product Specifications

0

Catalog

Frequently Asked Questions

Absolutely. Minnuo has a fast-responding pre-sales team. As long as I provide part drawings, you can recommend a suitable external cylindrical grinding machine within 10 minutes. For multiple machines or production lines, a complete configuration plan will be provided within 5 working days.

Yes. Our company has comprehensive manufacturing capabilities. Whether it’s machine structure, spindle speed, motor power, or control system, I can customize the external cylindrical grinding machine according to my specific machining requirements.

Our company equipped with high-end machining centers from top global brands, ensuring the precision and stability of all key components in each external cylindrical grinding machine. Every machine undergoes complete quality testing before delivery, with detailed inspection reports provided.

For standard models, we have stock available for fast delivery. For customized external cylindrical grinding machines, the delivery time is usually 30 to 45 working days, depending on the complexity of the project.

All machines come with a one-year warranty. During the warranty period, I can receive free repair services. If any issue arises, your support team offers 24/7 technical service via remote video, phone, or on-site assistance to help me resume production quickly.

External cylindrical grinding machines are ideal for precision grinding of external round surfaces, including shafts, sleeves, rollers, and pump bodies. They are suitable for various materials such as steel, stainless steel, and carbide, depending on wheel and process configuration.

Our external cylindrical grinding machines can achieve roundness and dimensional accuracy within ±0.002mm under standard conditions. For applications with strict surface finish requirements, I can also upgrade to high-precision spindles and dynamic balancing systems.

Yes. Our external cylindrical grinding machine supports modular upgrades and configuration changes. I can add automation, upgrade control systems, or change fixtures as needed. This flexibility helps me adapt to evolving production needs and extends the machine’s value over time.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763