Regular maintenance

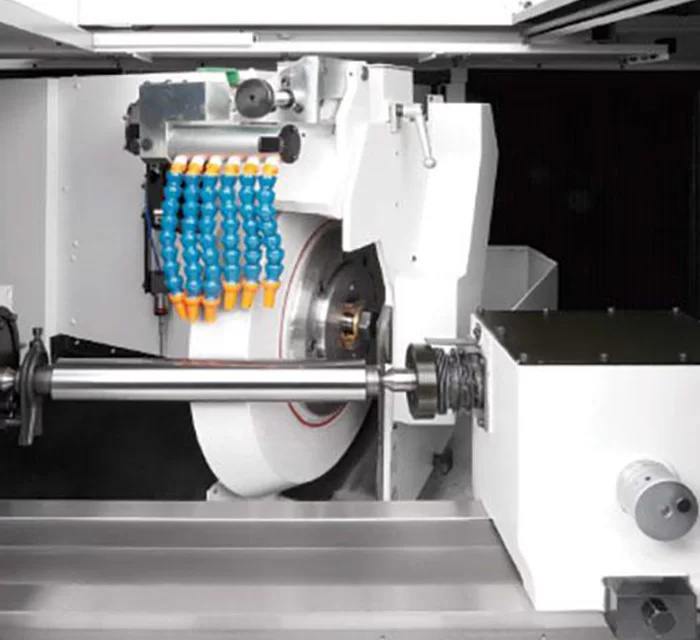

Ultra-Large Worktable CNC Vertical Grinding Machine MGK28160

-

Max table diameter : φ1600mm

-

Max. workpiece rotation range : φ1700mm

-

Max. workpiece height(maximum grinding depth): 500mm

Max Table Ø1600mm · Max Workpiece Ø1700mm · Max Grinding Height 500mm

The MGK28160 is an ultra-large worktable CNC vertical grinding machine built for heavy-duty, high-precision surface and cylindrical grinding of extra-large round components. With a maximum table diameter of Ø1600mm and capable of handling workpieces up to Ø1700mm in rotation range, this machine is optimized for large-scale, high-mass parts that demand extreme accuracy and repeatability.

MGK Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● Extra-Large Table: Supports parts up to Ø1700mm in diameter and 500mm height, with table load capacity exceeding 3 tons.

- ● Vertical Layout with Superior Rigidity: Ideal for thin-wall or eccentric mass components, allowing gravity-based clamping and minimal deflection during grinding.

- ● Advanced CNC Axis Coordination: Supports simultaneous OD, ID, face, taper, and chamfer grinding, programmable via FANUC, Siemens, or KND controllers.

- ● Heavy-Duty Spindle and Guideways: Designed for continuous industrial operation with stable performance and minimal thermal drift.

- ● Optional Automation Integration: Easily integrates with hydraulic clamping, robotic loaders, automatic gauging, and in-cycle wheel dressing.

Recommended Configurations

- ● Full-enclosure & mist coolant system: Improves safety and ensures thermal consistency during long grinding cycles.

- ● Dual grinding wheel setup: Enables OD and face grinding without secondary clamping.

- ● Auto dynamic wheel balancing: Minimizes vibration at high contact pressures.

- ● On-machine probing & compensation: Ensures part tolerance consistency over extended runs.

- ● Hydraulic 4-jaw or magnetic chuck: Adapts to complex or asymmetric parts safely.

Application Case

- ● Client: Offshore equipment manufacturer – Europe

- ● Workpiece: Ø1650mm stainless steel turbine base plate

- ● Setup: MGK28160 with magnetic chuck, dual wheel, and automatic dressing

- ● Results: Flatness controlled within 4.5 μm over entire face, OD roundness ≤ 2.0 μm, one-setup OD + face + chamfer grinding, improved overall production efficiency by 40% over legacy process. 4o mini

Product Specifications

0

Catalog

Frequently Asked Questions

Absolutely! As long as you provide the part drawings, whether for a single vertical grinding machine or a complete production line, a recommended solution can be provided in a short time. For a single machine, it usually takes about 10 minutes; for multiple machines, the full proposal can be ready in about 5 working days.

Yes. I can customize the spindle power, control system, grinding travel, automatic loading/unloading system, and more on a CNC vertical grinding machine according to the size, material, and machining requirements of my specific workpieces, achieving a perfect match with my production environment.

You can use it with confidence. The components are processed by high-precision mother machines, ensuring high machining accuracy and structural stability. Every vertical grinding machine is rigorously tested before delivery and comes with a complete quality inspection report.

If I choose a standard model, it can usually be delivered quickly. In-stock models can ship as fast as within three days. If I require a customized vertical grinding machine, the delivery time is usually 30 to 45 working days.

We can customize the machine structure, external dimensions, cooling and lubrication system, spindle configuration, control system, and automation modules based on actual production needs. The modular design of the vertical grinding machine also gives me more flexibility for future upgrades.

If you are processing large-size workpieces such as flanges, valve bodies, or ring-shaped parts, a vertical rotary surface grinding machine is especially suitable. Its rotary table structure allows me to efficiently finish precision grinding of large flat components.

We have in-house R&D capabilities, real customer cases, support for customization, and complete after-sales service as vertical grinding machine manufacturers. A stable export record and responsive service ensure long-term, reliable cooperation.

You need to evaluate from several aspects: whether the machine meets my machining requirements, whether flexible customization is supported, whether the quality is stable, and whether technical service is in place. If a manufacturer performs well in solution planning, after-sales response, and application support, they are more likely to be the ideal best vertical grinding machine manufacturer.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763