Regular maintenance

Long-bed Heavy Duty Lathe Machine CK84125

-

Max.swing diameter over machine bed : 1400mm

-

Max.swing diameter over cutting tool carriage: 1250mm

-

Max.work-piece weight: 32T

-

Max.work-piece length: 2500-6000mm

Triple-bearing spindle support • Up to 32T load capacity • CNC feed & speed control • Servo tailstock movement

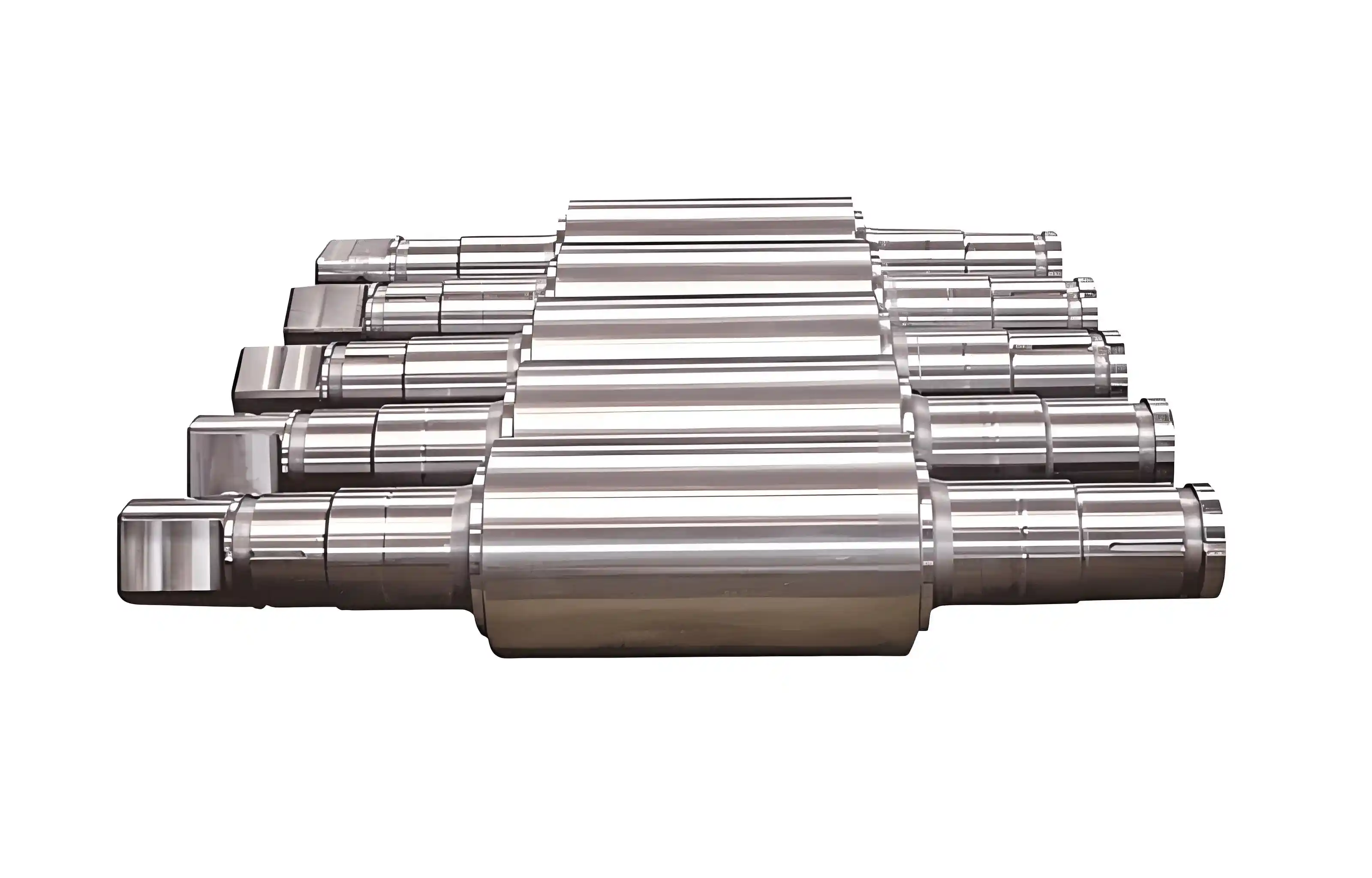

The CK84 Series Heavy Duty CNC Roll Lathe is built for precise turning and repair of large rolls, offering strong spindle support, servo tailstock, and programmable control for high-load stability. Ideal for steel mills and heavy industries, it features efficient chip removal and forced lubrication for safe, reliable operation.

CK84 Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● Three-Support Spindle Structure: The spindle utilizes a triple-bearing support configuration, delivering outstanding rigidity and vibration resistance during deep or interrupted cuts. It ensures stable performance when machining large-diameter rolls weighing up to 32 tons.

- ● Optimized Drive & Feed System: The CK84 features a CNC-controlled variable speed drive, allowing precise adjustments to spindle rotation and feed rates for both roughing and finishing tasks. All parameters can be modified easily via the control panel, enhancing efficiency and surface quality.

- ● Efficient Chip Removal System: A side-mounted chip conveyor efficiently removes large chip volumes generated during heavy turning, improving operator safety and reducing manual cleanup to maintain a productive workspace.

Recommended Configurations

- ● Spindle System: High-torque Spindle, High-power Spindle, Center Water Outlet Spindle

- ● Feed System: High-precision Servo Motor, Stepper Motor, Heavy-duty Square Linear Guides

- ● Cooling System: Centrifugal Pump, Vibration Pump, Water-soluble Coolant, Oil-based Coolant

- ● CNC Control System: High-performance CNC System (FANUC, Siemens, GSK, KND, SYNTEC, Mitsubishi, etc.)

- ● Tooling System: Large Square Ram Tool Holder, Turret Tooling System, Electric Turret, Large-size Tool Holding System

- ● Measurement and Monitoring: Heidenhain Linear Scales, Tool Breakage Detection System, Renishaw OMP60 Workpiece Probe, Renishaw TS27R Tool Setting Probe

- ● Other Configurations: Lubricated Manual Tailstock, Strong Magnetic Chain-type Chip Conveyor, Automated Loading/Unloading Gantry

Application Case

- ● Client: Steel Mill – Southeast Asia

- ● Component: Forged backup rolls for hot rolling lines (φ1200 mm × 5500 mm, 28 tons)

- ● Setup: CK84-1250 CNC lathe with 4-jaw hydraulic chuck, steady rests, DRO system

- ● Results: • Machining Time Reduction: 35% shorter cycle compared to legacy lathe • Precision Achieved: Roundness deviation ≤ 0.02 mm • Surface Finish: Ra ≤ 1.6 μm on finishing pass

- ● Customer Feedback: “The CK84 significantly boosted our roll reconditioning capacity while maintaining tight tolerances. It’s now the centerpiece of our roll workshop.”

Product Specifications

0

Catalog

Frequently Asked Questions

Minnuo heavy duty lathes are designed for large, long, and heavy components, such as wind turbine shafts, marine propeller shafts, large rollers, pressure vessel flanges, and oil drilling equipment. These machines are ideal for industries like energy, marine, aerospace, and heavy machinery.

Our standard heavy duty cnc lathes can handle turning diameters up to 2,000 mm, lengths up to 10,000 mm, and load capacities over 15 tons. Custom models can be configured for even larger sizes and heavier components.

Minnuo heavy duty lathes feature one-piece cast iron beds, extra-wide guideways, large spindle bores, and reinforced tailstocks. These structural features ensure exceptional rigidity and vibration absorption during heavy cutting operations.

Yes! Just send us your part drawings or specifications, and Minnuo’s engineering team will recommend the suitable heavy duty lathe model within 10 minutes. For full production lines, we will provide a tailored solution within 5 working days.

Absolutely! We offer customizations including bed length, spindle bore diameter, main spindle power, chuck size, and steady rest options, as well as integration with automation systems to meet your exact processing needs.

Each machine is manufactured using premium processing equipment, with precision hand scraping of contact surfaces, and undergoes dynamic balancing tests, laser alignment checks, and full-function dry runs before shipment. Inspection reports are delivered with the machine.

Standard models can be delivered within 15–20 working days. For large or fully customized machines, the delivery time is usually 30–60 working days, depending on complexity and workload.

We offer a one-year warranty, with 24/7 technical support. Our service team provides remote video diagnostics, phone consultations, and on-site assistance to solve any issues quickly. Spare parts support is guaranteed for 10+ years after purchase.

As a professional heavy duty lathe machine manufacturer, Minnuo offers direct factory sales. We will provide the most suitable quotation according to customers' requirements to ensure the highest cost - performance ratio.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763