Regular maintenance

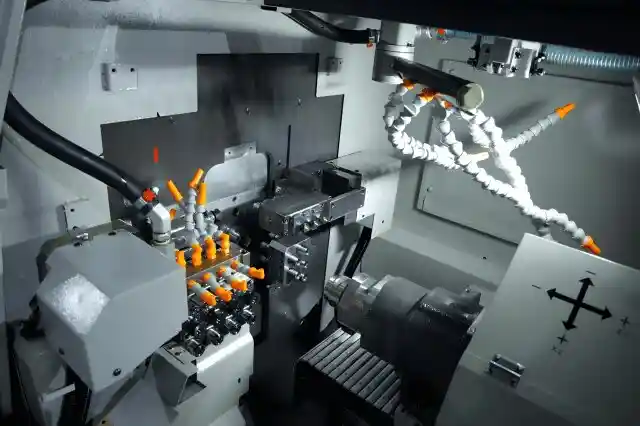

High-Speed Nine-Axis Twin-Spindle Swiss-Type Lathe AFR20-9

-

Maximum Bar Stock: 20 mm / 0.79″

-

Max Headstock Stroke w/ Guide Bushing:170 mm / 6.69″

-

Main Spindle Speed :200 – 10,000 rpm

Φ20mm Max Bar Stock · 170mm Headstock Stroke · 200–10,000 rpm Spindle Speed

The AFR20-9 is a 9-axis cnc lathe swiss type engineered for complex micro-component production. With twin spindles and independent gang slides, it supports simultaneous machining on both ends of the part. Its maximum headstock stroke of 170mm and ultra-high spindle speeds up to 10,000 rpm ensure high throughput and exceptional surface finish in tight-tolerance applications.

AFR Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● 9-Axis Complex Machining Supports multiple simultaneous operations, dramatically reducing cycle times for intricate parts.

- ● Twin Spindles with Independent Slides Enables true parallel processing—ideal for small-diameter parts requiring front and back operations.

- ● High-Speed Main Spindle Operates from 200 to 10,000 rpm—ensuring stable performance across a wide range of materials.

- ● Extended Headstock Stroke 170mm stroke capability allows for deep cutting and long-part machining in a single setup.

- ● Swiss-Type Sliding Head Design Maximizes support near the cutting zone—improving accuracy and surface finish on slender parts.

Recommended Configurations

- ● Automatic Guide Bushing System: Enhances precision for long and narrow parts.

- ● Coolant Through-Tool System: Increases chip evacuation efficiency for deep-hole drilling.

- ● Mist Collector: Maintains a clean and safe workspace during high-speed machining.

- ● Rotary Tool Attachments: Expands capability for off-center drilling and milling.

- ● Chip Conveyor: Automatically removes chips for uninterrupted operation.

Application Case

- ● Client: Medical Device OEM – Germany

- ● Use Case: Full-cycle machining of surgical implant screws and catheter components

- ● Setup: AFR20-9 with guide bushing system, mist collector, and rotary tool modules

- ● Results: Machining accuracy held within ±0.003 mm, surface finish consistent at Ra ≤ 0.8 μm, efficiency improved by 2.5× over previous fixed-head turning

- ● Client Feedback: “The AFR20-9 brought both speed and micron-level precision to our production line—an absolute game-changer for medical parts.”

Product Specifications

0

Catalog

Frequently Asked Questions

Our Swiss type lathes are ideal for small-diameter, long, and high-precision parts, such as medical implants, aerospace pins, micro shafts, watch parts, and automotive precision components.

Unlike traditional lathes, Swiss type lathes use a sliding headstock and a fixed guide bushing, allowing the material to move close to the cutting tool, reducing deflection and achieving extremely high precision for slender parts.

Minnuo cnc swiss type automatic lathes achieve positioning accuracy within ±0.002 mm, and surface finish up to Ra0.2μm, perfect for ultra-precision industries like medical and electronics.

Of course! Minnuo’s pre-sales engineers will recommend the right Swiss type lathe model within 10 minutes after reviewing your part drawing. For full production line setups, we can offer detailed solutions within 5 working days.

Absolutely. We offer customizations including spindle power, number of live tooling positions, back working capabilities, guide bushing types, and bar feeder integration to meet your special production needs.

We use high-quality hardened steel structures, high-precision spindles, and all machines undergo thermal stability tests, geometric precision tests, and full trial machining before shipment.

Standard models can be delivered within 20–25 working days. For customized configurations, delivery times are typically 30–45 working days.

Minnuo provides a one-year warranty, 24/7 technical support, and remote video diagnostics. We also ensure 10+ years of spare parts supply and offer operator training services upon request.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763