Regular maintenance

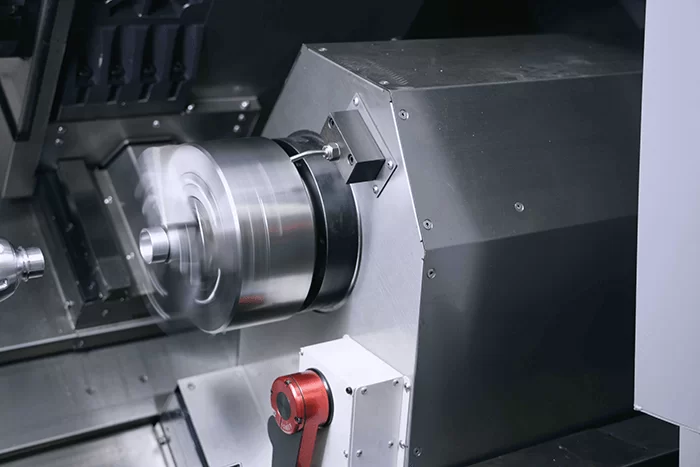

Double spindle CNC lathe MN700D

-

Max work piece length: 450mm

-

Max.turning diameter (disc): 280mm

-

Max. bar capacity: 49mm

-

Max. swing over bed: 700mm

Twin-Spindle · Compact Power · High-Efficiency Production

The MN700D is a compact yet powerful cnc turning and milling machine with twin spindles, designed for high-speed, high-accuracy machining of bar-fed or disc-type parts. Its dual-spindle layout enables full front and back machining in a single setup, significantly reducing cycle time and labor.

CNC turning and milling machine MN700D

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Machine Features

- ● Twin Spindles for Full Two-Side Machining: Allows automatic transfer of parts from main to sub-spindle, completing both ends in one cycle.

- ● Compact Slant Bed Design: 45° slant bed structure ensures better rigidity, chip evacuation, and ease of maintenance in high-volume use.

- ● High-Speed Precision Turning: Optimized spindle drive system with 4000 rpm max. speed and smooth servo axis control.

- ● Bar Feeding Compatible: Supports up to Ø49mm bar stock with auto bar feeder integration, enabling lights-out production.

- ● Automatic Tool Turret: 8 or 12-position servo turret for fast, precise tool changes and flexible tooling layouts. Y-axis powered tool turret for added milling capabilities.

Recommended Configurations

- ● Spindle Configuration: High-speed Electric Spindle, Dual Spindle System, Y-axis Powered Tool Turret

- ● Tooling System: Servo Tool Turret, Tool Compensation System

- ● Clamping System: Hydraulic Clamps, Pneumatic Clamps, Mechanical Clamps, Magnetic Clamps

- ● Feed and Drive System: Linear Drive, Ball Screws, Servo Motors

- ● Cooling and Lubrication System: Internal Cooling System, External Cooling System, High-pressure Cooling System

- ● Control System: High-performance CNC System (FANUC, Siemens, GSK, KND, SYNTEC, Mitsubishi, etc.)

- ● Other Configurations: Robot Arm, Renishaw OMP60 Workpiece Probe, Renishaw TS27R Tool Setting Probe, Chain-Type Chip Conveyor, Oil Mist Collector

Application Example

- ● Customer: VietTorque Auto Parts Co., Ltd.

- ● Workpiece: Ø42mm × 280mm steel shaft for sensor housing.

- ● Setup: MN700D + 12-tool turret + sub-spindle + bar feeder.

- ● Result: Reduced processing time by 40%, improved.

- ● concentricity tolerance to within 0.01mm, and cut operator workload by 60%.

Product Specifications

| Specifications | unit | MN700D |

|---|---|---|

| Max.swing dia.over bed | mm | 700 |

| Max.swing dia.overslide | mm | 350 |

| Max.work piece length | mm | 650 |

| Max.bar capacity | mm | 50 |

| Max.processing diameter(plate) | mm | 280 |

| Spindle nose | GB59001 | A2-6 |

| spindle bore | Φ/mm | 65 |

| Spindle speed | r/mm | 500-3000 |

| Spindle shift mode | / | Stepless speed regulation |

| Spindle motor power | KW | 11 |

| Chucktype | / | Hydraulic chuck |

| Chuck size | Inch | 8 |

| Xaxis rapid traverse | m/min | 18 |

| Y axisrapid traverse | m/min | 6 |

| Z axis rapid traverse | m/min | 18 |

| Xaxis servo motor torque | N.m | 15 |

| Y axis servo motor torque | N.m | 6 |

| Z axis servo motor torque | N.m | 15 |

| X axis travel | mm | 200 |

Catalog

Frequently Asked Questions

Minnuocnc turning and milling machines are highly versatile, suitable for cylindrical parts, complex shapes, and parts requiring both turning and light milling, such as shafts, sleeves, valve bodies, and aerospace components. They are widely used across automotive, aerospace, medical, and general manufacturing industries.

CNC turning and milling machine offer higher automation, multi-functionality, and greater precision. They can integrate turning, drilling, tapping, and milling operations in one setup, significantly reducing setup times and improving overall machining efficiency.

Minnuo cnc turning and milling machine achieve positioning accuracy within ±0.005mm and repeatability of ±0.003mm, ensuring high consistency and precision even for complex workpieces.

Yes! Minnuo’s pre-sales team can quickly recommend the right mill and turn machine model within 10 minutes based on your part drawings. For production lines involving multiple machines, we will deliver a full solution within 5 working days.

Absolutely! We provide full customization options for mill and turn machine, including spindle configurations, turret types, live tooling systems, motor powers, Y-axis functions, and more, to perfectly match your production needs.

Our mill and turn machines are built with premium-grade machining equipment and undergo full dynamic precision testing, spindle alignment verification, and complete operational testing before shipment. Detailed inspection reports are provided with every machine.

Standard models are typically ready for shipment within 7–10 working days. Customized models generally require 30–45 working days, depending on specific requirements.

Minnuo provides a one-year warranty for all mill and turn machine. Our after-sales team offers 24/7 support via phone, video call, or on-site service. Any equipment malfunctions within the warranty period are repaired free of charge to ensure continuous production.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763