Regular maintenance

Economic Single Column Vertical Lathe C5123G×H/10

-

Max.Turning diameter: 2300mm

-

Max. height of workpiece: 1250/1600/1800mm

-

Max. weight of workpiece: 10T

-

Table diameter: 2000mm

1250/1600/1800mm Max Workpiece Height · 10T Max Workpiece Weight · φ2000mm Table Diameter

The C51 Series Conventional Single Column Vertical Turret Lathe is designed for precise turning of large, heavy workpieces up to Ø2300 mm and 10 tons, combining robust construction with PLC-controlled flexibility. Featuring a rolling guide table, OMRON PLC, and quality electrical components, it ensures stable performance and easy maintenance for heavy-duty industrial applications.

C51 Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● PLC-Controlled Speed System: Incorporates PLC-controlled solenoid valves for automatic gear shifting, ensuring smoother and more reliable speed transitions compared to traditional manual systems.

- ● Low-Friction Sliding Mechanism: All sliding surfaces are coated with soft guideway belts to minimize stick-slip behavior, reduce friction, and extend the lifespan of the guideways under continuous operation.

- ● Square Ram & Extended Stroke: Features a square-section ram with an optional five-station turret. The column height is adjustable, and the ram stroke is extendable, allowing for efficient processing of deep or complex workpieces.

- ● High-Capacity Rotary Table: Utilizes a preload-optimized rolling guide rotary table for high precision and load-bearing capacity. Spray lubrication ensures consistent performance while eliminating maintenance issues common in hydrostatic systems.

- ● Industrial-Grade Electronics: Equipped with OMRON PLC control and Schneider or Siemens electrical components, delivering industrial-grade reliability and global support coverage for enhanced uptime and serviceability.

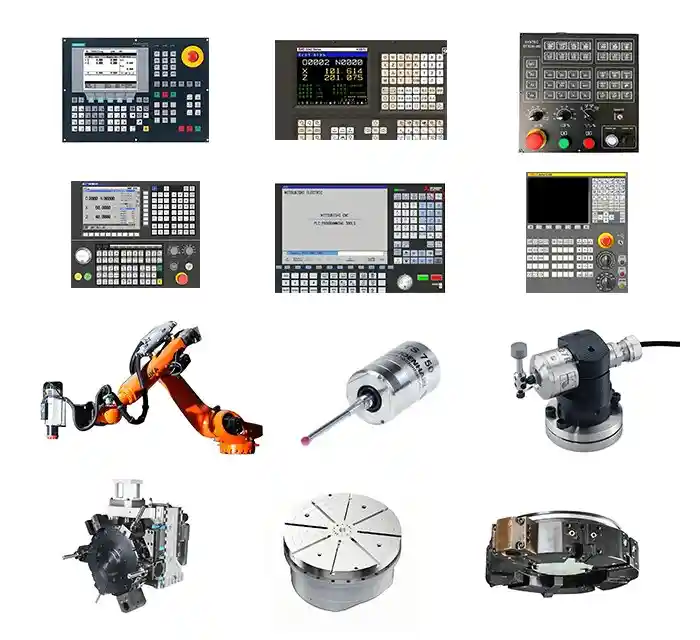

Recommended Configurations

- ● Digital Readout (DRO) System: Delivers real-time visual feedback for both tool and table positioning, significantly enhancing machining accuracy and operational control.

- ● Hydraulic 4-Jaw Chuck: Provides flexible and secure clamping for large or irregularly shaped workpieces, ensuring stability during heavy-duty operations.

- ● Extended Column & Ram Option: Offers increased Z-axis travel to accommodate deep cavities or tall components, expanding the machine’s processing range and application versatility.

- ● Protective Enclosure + Mist Collector: Enhances workplace safety and improves air quality by containing debris and capturing mist during extended or high-speed machining cycles.

- ● Manual or Automatic Tool Turret: Available with up to five stations, the turret allows multi-step machining without manual tool changes, increasing efficiency and reducing cycle time.

Application Case

- ● Client: Gear Manufacturing Facility – Eastern Europe

- ● Workpiece: Ø2000 mm gear blanks with integrated hubs

- ● Workpiece: Ø2000 mm gear blanks with integrated hubs

- ● Results: • Dimensional consistency: Maintained within ±0.02 mm • Surface finish: Improved to Ra ≤ 1.6 μm • Cycle time: Reduced by 20% vs. legacy vertical lathe

- ● Customer Feedback: “The C51 delivers the precision of a CNC vertical lathe with the simplicity of manual control. Ideal for our medium-volume gear blank operations.”

Product Specifications

0

Catalog

Frequently Asked Questions

Minnuo vertical turret lathes are ideal for heavy, large-diameter disc or ring-shaped workpieces, such as flanges, valve bodies, turbine housings, large bearings, and gearbox cases.

A VTL provides better support for large, heavy parts, minimizes deformation during machining, offers easier loading/unloading, and allows multi-tool machining with a turret for improved efficiency.

Our VTLs support turning, facing, boring, grooving, threading, and optional live tooling functions for drilling and light milling — all in one setup.

Yes! Minnuo's technical team can recommend a matching vertical turret lathe model within 10 minutes based on your workpiece drawings. For full production line solutions, we deliver a detailed plan within 5 working days.

Absolutely. We can customize table diameter, machine height, spindle motor power, turret type, number of tool stations, and even add live tooling systems according to your specific needs.

Our VTLs use high-grade Meehanite cast iron beds, precision-ground guideways, and are subjected to geometric accuracy testing, spindle radial runout inspection, and trial machining before delivery.

Standard models are usually delivered within 20–30 working days. Fully customized VTLs typically require 45–60 working days depending on complexity.

Minnuo provides a one-year warranty and 24/7 technical support. We also offer remote troubleshooting, on-site repairs, and long-term parts supply support for more than 10 years after purchase.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763