Regular maintenance

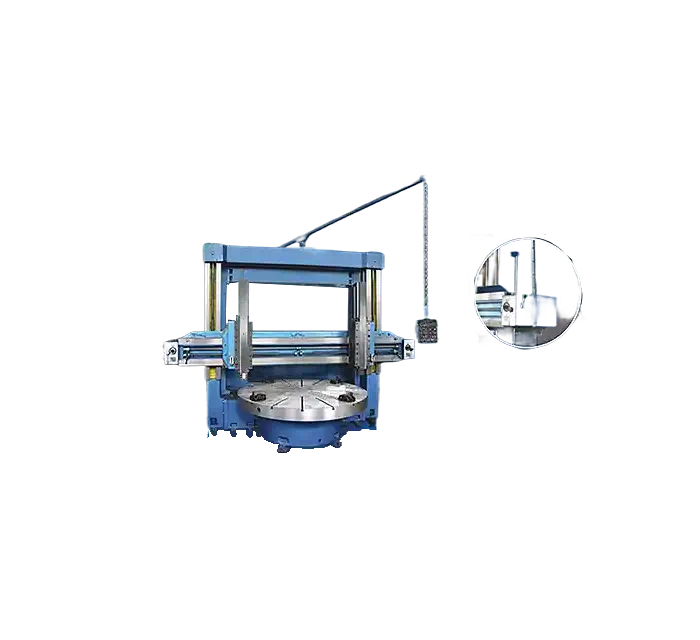

Ram-type Vertical Turret Lathe CA5240E × H/W

-

Max Turning diameter: 4000mm

-

Max height of workpiece: 2100/2600/3200/3500mm

-

Max weight of workpiece: 25/32T

-

Table diameter: 3600mm

Up to 40T load • Ø4500 mm table • 16-step gear transmission • Eccentric-load stability

The CA52/CQ52/C52 Series double-column turret lathe is built for large, heavy components up to Ø6000 mm and 40 tons, ideal for energy, petrochemical, and heavy machinery industries. With OMRON PLC control, precision gear transmission, and a hydrostatic table, it ensures stable, high-performance machining under extreme loads.

CA52/CQ52/C52 Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● Reinforced Base & Table Structure: An enlarged table base with a circular guideway increases load capacity (25T–40T), enhances rotary smoothness, and improves tolerance for eccentric loads—ideal for oversized flange and ring-type workpieces.

- ● Precision Gear Transmission System: Features a larger main gear and optimized gear ratio (1.25–40 rpm in 16 steps), delivering higher output torque without increasing motor power. This reduces gear stress and extends the transmission system's service life.

- ● Reliable PLC Control System: Utilizes an OMRON programmable logic controller for stable, logic-driven operation and simplified troubleshooting, particularly beneficial for complex turret turning routines.

- ● Heavy-Duty Structural Design: With enlarged columns, beams, and cross-beams (models CA5250 and above), the structure offers significantly improved rigidity to handle high-force turning of large and tall components.

- ● Upgraded Hydraulic System: Equipped with a high-capacity oil tank to maintain stable hydraulic pressure, enabling continuous operation while minimizing system fatigue and reducing maintenance frequency.

Recommended Configurations

- ● Digital Display Readout (DRO): Provides real-time feedback for vertical and horizontal positioning, enhancing manual setup precision and reducing alignment errors during operation.

- ● Turret Head with Multi-Tool Stations: Supports efficient multi-step machining such as roughing, finishing, chamfering, and grooving without the need for re-clamping, improving cycle time and consistency.

- ● Heavy-Duty 4-Jaw Manual or Hydraulic Chuck: Designed to securely clamp large-diameter or irregular workpieces with high repeatability and strong holding force for heavy-duty cutting.

- ● Cooling and Chip Management System: Equipped with directional coolant nozzles and integrated chip trays to ensure effective heat dissipation and chip evacuation during deep or continuous cutting.

- ● Side Tool Holder (Optional): Provides additional flexibility for inner diameter boring, contour profiling, or other secondary machining operations in a single setup.

Application Case

- ● Client: Heavy Equipment Manufacturer – Poland

- ● Workpiece: Ø5200 mm wind turbine hub (height: 3100 mm, weight: 38 tons)

- ● Setup: CA5250 with constant-flow hydrostatic table, DRO, turret head, and hydraulic chuck

- ● Results: • Turning Accuracy: Roundness deviation ≤ 0.03 mm • Machining Efficiency: 28% cycle time reduction vs. previous conventional machine • Surface Finish: Achieved Ra ≤ 1.6 μm after fine turning

- ● Client Feedback: “The CA52 machine’s enhanced stability and high-load tolerance allow us to complete oversized components in a single setup. It’s become the cornerstone of our large-part machining line.”

Product Specifications

0

Catalog

Frequently Asked Questions

Our vertical turret lathe machines are ideal for machining heavy, large-diameter, and short-length workpieces, such as flange parts, bearings, valves, and large gear blanks. They are particularly suited for industries like aerospace, wind energy, heavy machinery, and shipbuilding.

Minnuo vertical lathes achieve positioning accuracy within ±0.01mm and surface roughness up to Ra0.8μm, ensuring excellent precision even for complex contour turning operations.

Yes, our vertical turret lathes are designed for both heavy roughing and precision finishing. Equipped with high-rigidity structures, powerful spindles, and optional live tooling systems, they meet diverse turning requirements in one setup.

Absolutely! Minnuo Company has a strong and fast-responding pre-sales team. If you provide the parts drawings or specifications, we can recommend the appropriate vertical lathe model within 10 minutes for a single machine. For a full production line, we will offer a comprehensive solution within 5 working days.

Yes, Minnuo offers complete customization options for vertical turret lathes, including changes to spindle speed ranges, chuck sizes, motor power, tool turret types, and even special clamping systems to fit your specific production needs.

Our vertical turret lathe machines are manufactured using top-brand machining centers for parts processing, ensuring high-precision assembly. Each machine undergoes strict geometric accuracy tests and dynamic balancing tests. Quality inspection reports are provided with every shipment.

For standard vertical turret lathe models, we maintain stock and can arrange fast delivery within 7–10 days. Customized vertical lathes are usually delivered within 30–45 working days, depending on specific customer requirements.

All Minnuo vertical turret lathe machines come with a one-year warranty. We offer 24-hour technical support through video calls, phone, or on-site services. During the warranty period, any equipment faults are repaired free of charge. Our after-sales team ensures fast troubleshooting to keep your production line running smoothly.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763