Regular maintenance

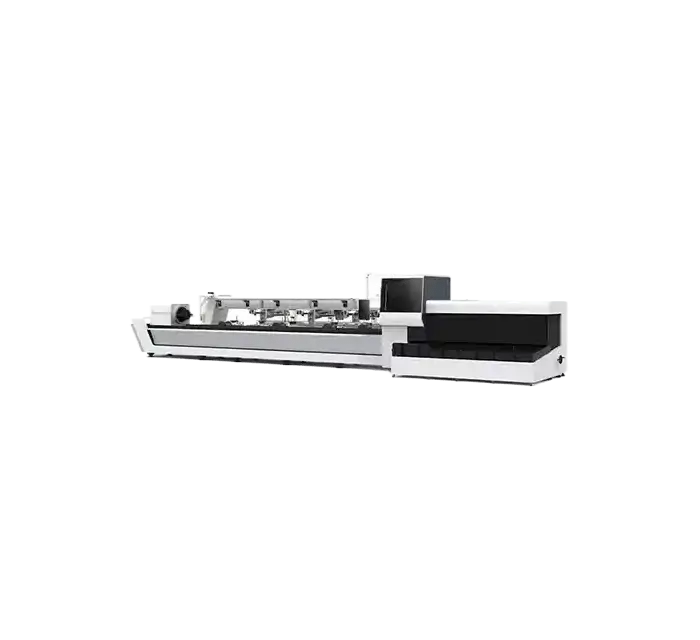

3D 5-Axis Beveled Laser Cutting Machine MN-h3000

-

Power: 3Kw-60Kw

-

Working width: 3015/4025/6025/8025/12025mm

-

Max. load weight: 374lbs

Power: 3kW–60kW · Working Widths: 3015 to 12025mm · Max Load: 374 lbs

The MN-h3000 is a high-performance 3D 5-axis laser cutting machine engineered for ultra-flexible beveled cuts on large and complex metal components. With available working widths from 3015mm up to 12025mm, and laser power configurations ranging from 3kW to 60kW, it meets the needs of automotive, aerospace, energy, and high-precision fabrication industries.

MN-h3000 Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● True 5-Axis Bevel Cutting Head: Supports ±135° rotation and ±45° tilting for multi-surface and edge-angle cutting in a single pass.

- ● Wide Table Range (3015–12025mm): Flexible to scale for small parts or oversized panels, pipes, and structural beams.

- ● Laser Power Range (3kW to 60kW): Easily adaptable for mild steel, stainless, aluminum, brass, and thick alloy plate cutting.

- ● Real-Time Motion Compensation System: Advanced CNC algorithms maintain precision during multi-axis movement, especially on uneven surfaces or curves.

- ● Modular Base + Gantry System: Supports custom line layouts, expandable production lines, and robotic loading integration.

Recommended Configurations

- ● Tube & Profile Rotational Support: Enables precision tube/pipe bevel cutting up to 12m length.

- ● Automatic Nozzle Changer: Reduces downtime and adapts to multiple material thicknesses.

- ● 3D Scanner + Height Tracking System: Maintains consistent focus on curved or angled surfaces.

- ● Robotic Arm Integration (Optional): Ideal for smart factories and continuous production lines.

- ● Fume Extraction + Water Cooling System: Enhances safety and cutting quality during high-power operation.

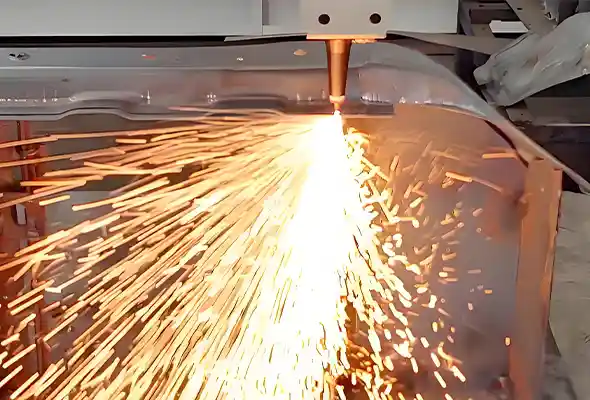

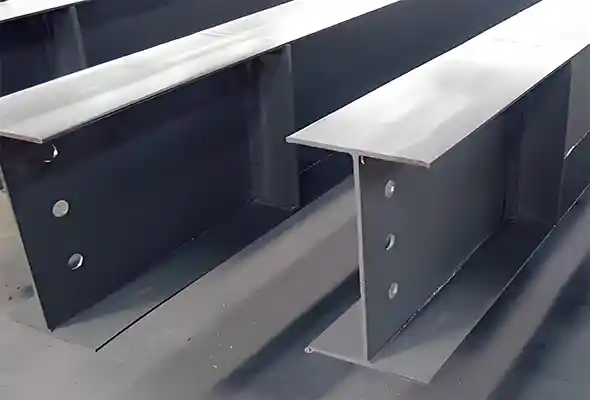

Application Case

- ● Client: Automotive chassis supplier – Germany

- ● Workpiece: 1.8mm thick high-strength steel structural beams, length 4025mm

- ● Setup: MN-h3000 (4025 version) + 6kW laser + auto bevel adjustment + height sensor

- ● Results: Edge precision: ≤ ±0.05mm Bevel cut angle repeatability: ≤ ±0.2° Production time per part: reduced by 40% Reduced secondary grinding and post-processing Improved weld preparation consistency across all units

Product Specifications

| Specification | Unit | 5 axis laser cutter |

|---|---|---|

| Power | kw | 3-60 |

| Working width | mm | 3015/4025/6025/8025/12025 |

| Max.load weight | lbs | 374 |

| Max.positioning speed | m/min | 170 |

| Max.linkage speed | m/min | 240 |

| Z-axis travel | mm | 100 |

| Max.positioning acceleration | G | 2.4 |

| Power supply | three-phase 380V/50/60Hz |

Catalog

Frequently Asked Questions

Laser cutting machine for metal is widely used for high-precision cutting of various metal materials such as carbon steel, stainless steel, aluminum sheets, copper sheets, and galvanized sheets. It is commonly applied in industries like sheet metal processing, electrical cabinets, automotive parts, and elevator manufacturing, making it the preferred equipment in the metal processing field.

A wood laser cutting machine is specifically designed for non-metal materials such as wood, acrylic, and leather, and usually comes with a CO2 laser cutting machine source. A glass laser cutting machine requires higher precision and cooling control. Different types of laser cutting machines are suited for different material characteristics. We will recommend the most suitable type based on your application.

Absolutely! Minnuo has a strong and responsive pre-sales engineering team. As long as you provide part drawings, whether for a single laser cutting machine or an automated cutting line, we can recommend a suitable solution within 10 minutes. For multi-machine configurations, a complete solution will be provided within 5 working days.

We can customize different specifications of CNC laser cutting machines based on your cutting material, thickness, sheet size, and production line cycle requirements. Options include laser power, cutting platform size, automatic loading and unloading systems, and dust extraction modules to ensure precise matching and production line integration.

We use top-tier laser sources and servo systems from world-class brands, combined with high-precision base machines and our own control systems to ensure the laser cutting machine delivers consistent performance and stability during long-term operation. Each machine undergoes full inspection and testing before delivery and comes with a quality inspection report.

For standard laser cutting machines, we usually have inventory for fast shipment. For customized models, the delivery time is generally 30–45 working days, depending on configuration complexity and production scheduling.

All equipment comes with a one-year warranty. During the warranty period, we provide free repair services in case of faults. We also offer 24-hour remote video technical support and on-site service when necessary to ensure stable equipment operation and quick production recovery.

The laser cutting machine price varies based on factors such as laser power, cutting size, laser source brand (e.g., Raycus / IPG), inclusion of automatic loading systems, and control system functions. Minnuo will provide a transparent and detailed quotation based on your actual needs, with options to include tax and shipping.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763