Regular maintenance

Electric Servo Press Brake Machine EP-35T1250

-

Bending Capacity: 35T

-

Y-axis Servo Motor::6.5KW

-

Bending Length: 1250mm

-

Column Pitch: 1130

Bending Capacity: 35 Tons · Bending Length: 1250mm · Y-Axis Servo: 6.5 kW

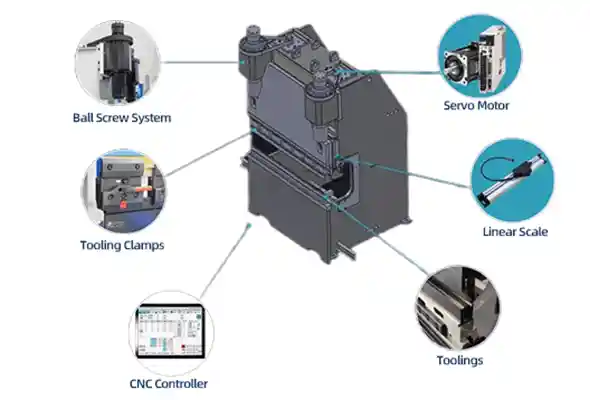

The EP-35T1250 is a compact, energy-efficient electric servo press brake designed for precision sheet metal bending. With a bending force of 35 tons, a bending length of 1250mm, and a 6.5 kW Y-axis servo motor, this machine provides quiet, clean, and repeatable bending ideal for modern manufacturing environments.

EP Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● Fully Electric System (No Hydraulic Oil): Reduces maintenance, eliminates leaks, and improves energy efficiency, providing a more sustainable and cost-effective solution.

- ● Precise Servo-Controlled Y-Axis: Delivers consistent bending results with programmable multi-step operations, ensuring accuracy and repeatability in every cycle.

- ● Compact Footprint for Space-Conscious Workshops: Ideal for factories with limited floor space or for use in production cells, offering flexibility without sacrificing performance.

- ● High-Speed Bending with Low Noise: Quiet operation (≤70 dB) makes it suitable for indoor or office-adjacent environments, maintaining a comfortable workspace.

- ● CNC Control Compatibility: Supports Delem, ESA, or KND systems for multi-axis, multi-bend programming, allowing advanced control and customization of bending operations.

Recommended Configurations

- ● Multi-Axis CNC Back Gauge (X, R): Enables high-precision positioning for complex parts.

- ● Quick Clamp System for Tooling: Speeds up die changeovers, reduces downtime.

- ● Laser Angle Measurement System: Ensures consistent bend angles through real-time correction.

- ● Linear Front Support Arms: Provides stability during bending of longer or thin parts.

- ● Foot Pedal + Emergency Stop System: Enhances operator safety and workflow control.

Application Case

- ● Client: Electrical enclosure manufacturer (Southeast Asia)

- ● Workpiece: 1.5mm powder-coated steel panels for industrial switchboards

- ● Setup: EP-35T1250 + Delem DA-53T + X/R-axis back gauge

- ● Results: Bending angle accuracy: ±0.3° Cycle time per part: ~10 seconds Energy usage reduction: ~58% vs hydraulic press Noise level: < 70 dB in full operation Production downtime decreased by 35%

Product Specifications

| Specifications | Unit | EP-35T1250 | EP-43T2000 | EP-65T2500 |

|---|---|---|---|---|

| Bending Capacity | T | 35 | 43 | 65 |

| Y-axis Servo Motor | KW | 6.5 | 7.5 | 15 |

| Bending Length | mm | 1250 | 2000 | 2500 |

| Column Pitch | mm | 1130 | 1400 | 2100 |

| Throat Depth | mm | 410 | 410 | 410 |

| Daylight | mm | 470 | 470 | 470 |

| Slider Inclination | mm | ±30 | ±30 | ±30 |

| Y Rapid Speed | mm/s | 135 | 180 | 160 |

| Y Working Speed | mm/s | 50 | 50 | 50 |

| Y Retrack Speed | mm/s | 135 | 180 | 165 |

| X Rapid Speed | mm/s | 500 | 500 | 500 |

| R Rapid Speed | mm/s | 200 | 200 | 200 |

| Z1/Z2 Rapid Speed | mm/s | 400 | 400 | 400 |

| Y-axis | mm | ±0.01 | ±0.01 | ±0.01 |

| X-axis | mm | ±0.02 | ±0.02 | ±0.02 |

| R-axis | mm | ±0.1 | ±0.1 | ±0.1 |

| Z1/Z2-axis | mm | ±0.1 | ±0.1 | ±0.1 |

| Y Stroke | mm | 200 | 200 | 200 |

| X Stroke | mm | 500 | 500 | 500 |

| R Stroke | mm | 140 | 140 | 140 |

| Z1/Z2 Stroke | mm | 400 | 600 | 900 |

| Controller System | SL100-P4/6 | SL100-P4/6 | SL100-P4/6 | |

| Installed capacity | kVA | 15 | 15 | 25 |

| Dimension | mm | 1475x1358x2439 | 2020x1388x2439 | 2520x1700x2664 |

| Weight | kg | 3000 | 3300 | 5100 |

Catalog

Frequently Asked Questions

Efficient series CNC press brake machines are designed for mid-to-high-end customer needs. They offer higher repeat positioning accuracy, faster bending speeds, and enhanced automation integration. These machines are ideal for high-precision and high-efficiency mass production, and are especially suitable for integration with robotic production lines.

Operating a brake press machine is not complicated. We provide operation manuals, instructional videos, and on-site training services. The CNC press brake machine is equipped with a graphical touchscreen interface that supports one-click angle adjustment and automatic calibration, making it easy and safe for beginners to learn and operate.

Absolutely! Minnuo has a strong and responsive pre-sales technical team. As long as you provide part drawings, whether for a single press brake machine or a complete automated bending line, we can usually provide a recommendation within 10 minutes. A complete multi-machine configuration can be delivered within 5 working days.

We have full mechanical processing and electrical control development capabilities. Based on your product material, thickness, bending angle, and precision requirements, we can customize the CNC press brake machine in terms of axis configuration, tonnage, control system, and tooling structure to meet specific process and production line needs.

We use hydraulic systems and servo motors from top international brands, combined with high-strength welded frames and self-developed control systems, to ensure that the press brake machine runs stably over long periods without deformation. Each machine comes with a complete quality inspection report and is ready for production upon delivery.

For standard models, we have inventory available for fast shipment. For customized press brake machines, the lead time is typically 30–45 working days, depending on the configuration complexity and production schedule.

Our press brake machines come with a one-year warranty. During the warranty period, any failure will be covered with free repair support. Minnuo provides 24-hour remote video support, telephone technical guidance, and on-site service if necessary to ensure quick production recovery.

A press brake machine is a device used to accurately bend sheet metal into specific angles. It is widely used in sheet metal processing, cabinet manufacturing, automotive parts, and other industries. It achieves high-precision and high-efficiency bending through the coordination of upper and lower dies and numerical control systems.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763