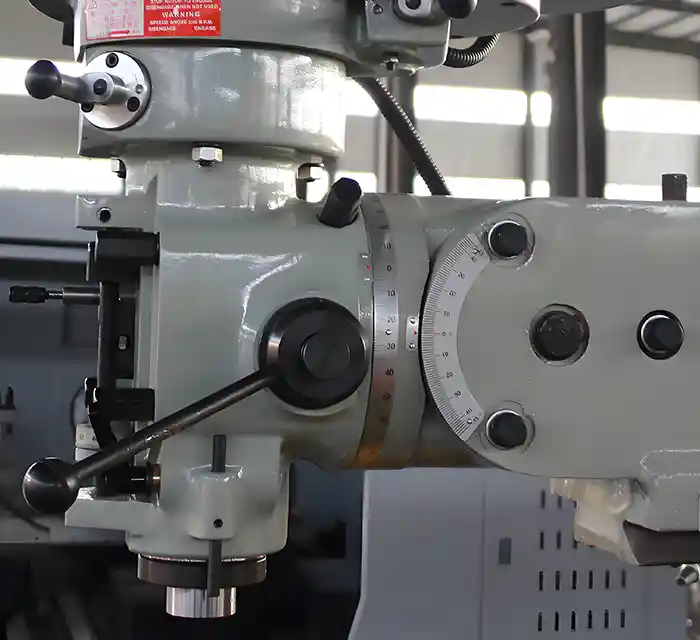

Regular maintenance

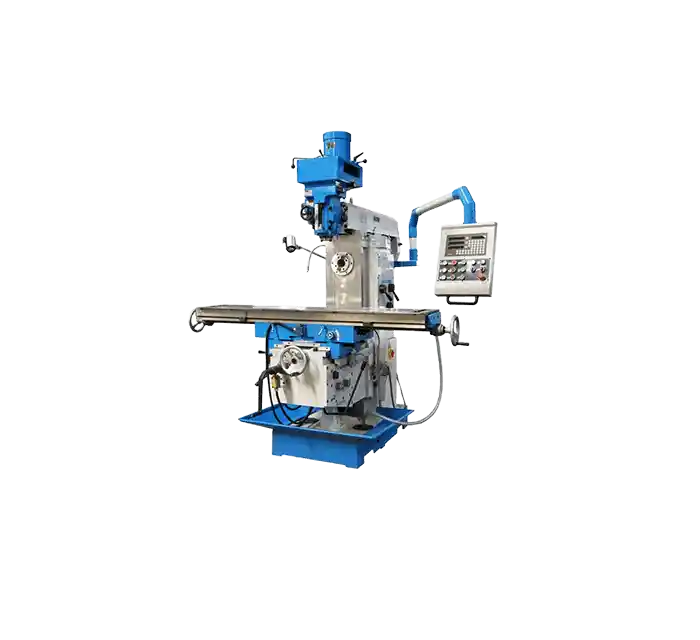

Long-Travel Turret Milling Machine XQ6332C

-

Table size: 1370×320mm

-

Table travel(X/Y/Z): 1000/380/400mm

-

Table feed(X/Y/Z): XY:30-830 Z:23-625

1370 × 320 mm Table • 1000 mm X-Axis Travel • Multi-Mode Feed with Precision Guideways

The XQ Series Long-Travel Turret Milling Machine features a heavy-duty cast structure and 1000 mm X-axis travel for precise, stable machining of large workpieces. With manual, motorized, and rapid feed modes, it offers flexibility and efficiency for general-purpose metal cutting.

XQ Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● Durable and Stable Structure: High-strength cast components with artificial aging treatment ensure long-term dimensional stability during continuous operations.

- ● Versatile Feeding System: Supports manual, motorized, and rapid feed with eight selectable speeds to minimize idle time and boost cutting efficiency.

- ● Extended Travel & Precision Guideways: Offers 1000 mm X-axis travel with hardened and ground guideways on all axes for enhanced positioning accuracy and long service life.

Recommended Configurations

- ● Spindle System: Adjustable speed spindle

- ● Worktable: T-slot worktable, ±45° rotating worktable, coordinate system,Rotary table

- ● Feed System: Manual feed system, electric feed adjustment

- ● Cooling and Lubrication System: Coolant spray device,Automatic centralized oil lubrication

- ● Clamping System: Standard fixtures, quick-change fixture device

- ● Clamping System: Standard fixtures, quick-change fixture device

- ● Other (Safety Protection System): 45° high-speed rotating tool turret, digital readout, dividing head, protective covers, emergency stop button and safety lock, LED work lamp,cutting disc

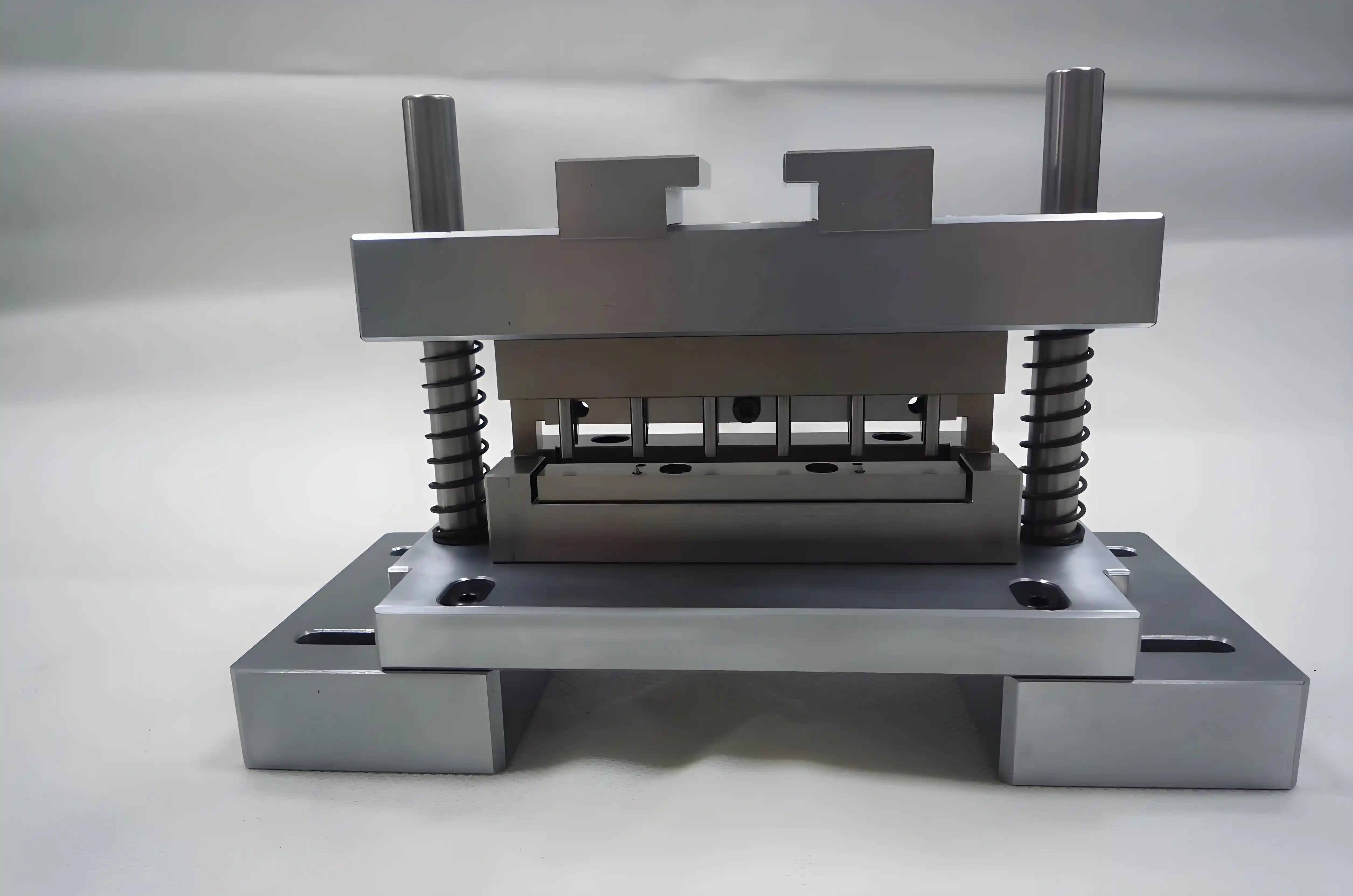

Application Case

- ● Client: Agricultural Machinery Manufacturer – Poland

- ● Use Case: Milling of gearbox mounting plates and fixture templates

- ● Setup: XQ Series with DRO and power feed attachments

- ● Results: • Achieved repeatability within ±0.02 mm across batches • Reduced setup and alignment time by 30% • Enhanced operator productivity due to intuitive controls

- ● Client Feedback: “The XQ milling machine’s rigidity and extended travel have made it a reliable asset for our tooling department. The versatility in feeding modes fits perfectly with our diverse machining tasks.”

Product Specifications

| Specification | Unit | XQ6332A | XQ6332C |

|---|---|---|---|

| Table size | mm | 1370×320 | |

| Table travel(X/Y/Z) | mm | 820/300/400 | 1000/380/400 |

| Rapid speed of table(X/Y/Z) | mm/min | 1335/1335/1000 | |

| Spindle taper | -- | 3HP:R8 or ISO30;5HP:ISO40 | |

| IS040 | |||

| Table feed(X/Y/Z) | mm/min | XY:30-830 Z:23-625 | |

| Distance between horizontal nose and table surface | mm | 75-475 | |

| Distance between spindle axis and ram surface | mm | 200 | |

| Spindle speed range | r/min | 43-3225 | |

| 65-4660(16 steps) | |||

| 12 steps 35-1500 | |||

| T-slots(No./width/pitch) | mm | 3/14/80 | |

| Arm travel | mm | 450 | |

| Main motor power | --- | 3HP or 5HP | |

| 3Kw | |||

| Torque of X/Y/Z axis AC servo motor | N.m | 15 | |

| Overall size | mm | 1820×1680×2350 | |

| Net weight | kg | 1750 | 1800 |

Catalog

Frequently Asked Questions

A turret milling machine is a type of milling machine with an adjustable turret head structure. The spindle can rotate at multiple angles, making it suitable for machining multiple surfaces or complex angles. Compared with a conventional vertical milling machine, it offers greater flexibility and versatility, making it ideal for repair work, mold making, and small-batch production with varied part designs.

Common turret milling machine parts include the spindle head, worktable, saddle, base, column, handwheels, and electrical control system. Maintenance is not complicated—you only need to regularly clean the guideways, check the lubrication system, and inspect the electrical circuits. A complete maintenance manual and operational training will also be provided.

Absolutely! Minnuo has a strong and responsive pre-sales team. As long as you provide part drawings, whether for a single turret milling machine or a complete production line configuration, we can provide a recommendation within 10 minutes. For multi-machine systems, a full configuration plan can be delivered within 5 working days.

We have full machining and manufacturing capabilities. You can customize the turret milling machine in terms of travel range, table size, spindle specifications, motor power, control system, and external sheet metal. Custom structural forms such as ram turret milling machines or vertical turret milling machines are also supported.

We are equipped with high-end machining centers from top international brands. All key components of the turret milling machine are manufactured with high precision in our own machining facility. Each machine undergoes strict debugging and testing before delivery, and is issued with a quality inspection report to ensure it is ready to use upon arrival.

For standard models, we have inventory available and can usually ship within a few days. For customized turret milling machines, the delivery time is generally 30–45 working days, depending on the configuration and production schedule.

The equipment comes with a one-year warranty. During the warranty period, you can receive free repair support in case of any failure. We offer remote video guidance, phone-based technical support, and on-site service when necessary to help you resume production quickly and minimize downtime.

The turret milling machine price varies depending on the configuration, size, whether it includes a CNC system, and whether it is customized. We will provide a formal quotation based on your specific requirements, including tax and shipping options, so you have a clear understanding of the full cost and can purchase with confidence.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763