Regular maintenance

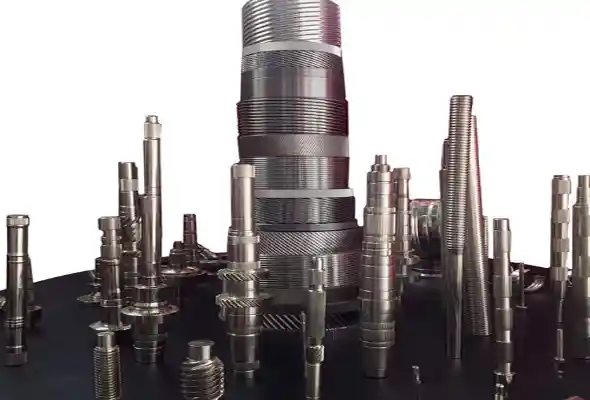

Heavy-Duty CNC In-Feed Thread Rolling Machine (3-Axis) R17NC-II

-

Max. rolling O.D.:φ75mm

-

Max. rolling length: 150mm

-

Max. rolling pressure: 17ton

φ75mm Rolling · 150mm Length · 17T Pressure

The R17NC-II (In-feed) is a high-capacity 3-axis CNC thread rolling machine, designed for short-length but heavy-duty thread forming applications. With a rolling capacity of up to φ75mm diameter and 17 tons of pressure, it delivers outstanding performance for internal and external threads, splines, and knurling operations in medium to hard metals.

R17NC-II Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● 3-axis CNC control for synchronized feed and die positioning

- ● Max. outer diameter capacity of φ75mm with up to 150mm length

- ● Delivers 17 tons of rolling pressure for aggressive thread/spline forming

- ● Ideal for short parts with in-feed constraints or features

- ● Supports threading, knurling, and spline formation in one setup

- ● High frame rigidity for vibration-free, high-load rolling operations

- ● Programmable via user-friendly CNC interface with thread library support

Recommended Configurations

- ● Hydraulic Workpiece Clamping Unit Ensures centering during high-force rolling

- ● Custom Spline/Thread Dies Designed for trapezoidal, metric, or involute profiles

- ● Integrated Cooling/Lubrication Unit Reduces heat and extends die life

- ● CNC Auto-Alignment Module Assures parallel die orientation and perfect engagement

- ● Protective Enclosure with Touch Screen Panel Enhances safety and usability

- ● Servo Control Upgrade For 5-axis or enhanced torque compensation

Application Case

- ● Client: Tier-1 Transmission Component Supplier – USA

- ● Use Case: Forming precision splines and lead threads on gear blanks with shoulders

- ● Setup: R17NC-II (3-axis) with involute spline dies, servo-controlled clamping, and mist lubrication system

- ● Results: Rolling depth accuracy: ±0.01mm, splined surface Ra: ≤ 1.2 μm, form cycle time: 12 seconds per part, client feedback: “This machine gave us consistent spline profiles across high-strength steel shafts with zero deformation. Cycle time and durability exceeded expectations.”

Product Specifications

0

Catalog

Frequently Asked Questions

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763