Regular maintenance

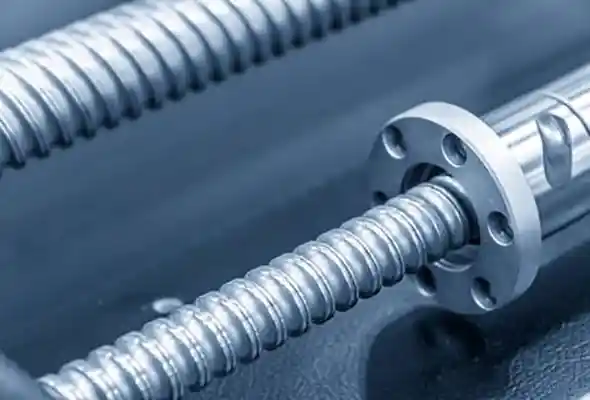

High-Precision Through-Feed Thread Rolling Machine R7NC

-

Max. rolling O.D.: φ10mm

-

Max. rolling length: 1,500mm

-

Max. rolling pressure: 7ton

φ10mm Rolling · 1500mm Length · 7T Pressure

The R7NC (Through-feed) is a compact, high-performance thread rolling machine engineered for continuous, uninterrupted thread formation along long workpieces. Capable of handling rolling lengths up to 1,500mm, this model supports through-feed rolling at speeds up to 195 min⁻¹, with 7 tons of pressure, ensuring excellent surface finish and thread consistency.

R7NC Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● Through-feed rolling for long workpieces up to 1,500mm

- ● Supports diameters up to φ10mm with excellent accuracy

- ● Generates high-strength rolled threads with a smooth surface finish

- ● CNC-adjustable feed and pressure for consistent thread depth and shape

- ● 7-ton rolling pressure handles tough materials like stainless and alloy steel

- ● Compact design integrates easily into production lines

- ● Minimal heat generation and no chip waste during operation

Recommended Configurations

- ● Precision Through-Feed Guide Rail Ensures consistent axial alignment

- ● Customized Thread Dies For different thread types including metric, UNC, trapezoidal

- ● Automatic Chip-Free Coolant System Enhances tool life and surface integrity

- ● Roller Loading Mechanism Increases automation speed and consistency

- ● Taper Alignment System Prevents thread deviation during long part rolling

- ● Safety Enclosure with Auto-Stop Sensor For uninterrupted and safe operation

Application Case

- ● Client: Construction Fastener Manufacturer – Turkey

- ● Use Case: Continuous thread rolling on M8–M10 tie rods and anchor bolts

- ● Setup: R7NC with automatic through-feed rails, chipless lubrication system, and dual-die station

- ● Results: Thread uniformity over 1,500mm: ≤ ±0.02mm deviation, output: increased from 80 to 195 pcs/hour, thread surface finish: Ra ≤ 1.6 μm, client feedback: “This machine revolutionized our long bolt production with precision and zero scrap.”

Product Specifications

0

Catalog

Frequently Asked Questions

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763